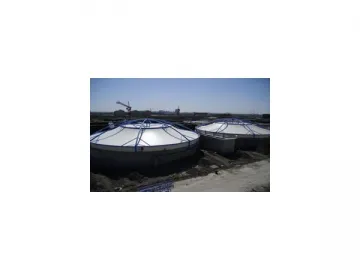

Sewage Treatment

Sewage Treatment Tank with Membrane

and Cover

PTFE or Silicone Coated Products for Sewage Treatment

With the rapid development of China’s economy and municipal infrastructure, the number of environmental projects is gradually increased. A great number of anaerobic digesters, sludge thickeners, biological flocculation tanks, and others in sludge treatment plants are established. They directly affect the life and health of human beings. In many cities, the sewage treatment tanks have been requested to be added with covers for the collection and disposal of wastewater.

Three Available Methods of Adding Covers on Sewage Treatment Tanks

1. Ordinary carbon steel frame plus sunlight plates

2. Stainless steel frame plus steel-glass plates

3. Membrane structure plus metal frame

Above-mentioned two structural forms of steel supports will be placed inside the top cover inevitably. In the covered tank, the concentration of corrosive gases will be doubled. The temperature will be ultra high under solar radiation. The internal steel structure will be corroded easily, and its service life usually ranges from 3 to 5 years. In other words, the whole structure will be reconstructed within a short time.

Practice shows that the durability of steel structure is not guaranteed in corrosive environments, even if it adopts stainless steel. Additionally, the cost is extremely high. However, the third type of membrane structure has successfully solved this problem, and also fully utilized the advantages of its raw material.

The membrane structure, also called fabric structure, is made from high-performance flexible fabrics. Its membrane surface is supported by internal air pressure. Alternatively, it will produce a certain pre-stressing by adoption of flexible steel wire rope and rigid supporting structure. Then, a new space structure system will be formed to cover a large space.

The membrane structure is generally divided into three types, including the air-supported type or inflatable type, tensioned type, and the frame-supported type. These three types have different structural features, architectural styles, and applications. In addition, an innovative structure is specially developed for a covered sewage-treatment tank. Its cover adopts anti-corrosive fluoro-carbon film. By means of anti-hanging method, this structure is adjustable to the corrosive environments in sewage treatment tanks.

Links:https://www.globefindpro.com/products/61251.html