Laminate Flooring Production Line

The laminate flooring production line involves several pieces of equipment as demonstrated below.

1. Boiler: It is used to provide necessary heat for the production process.

2. Hot press machine: The abrasion resistant overlay, decorative paper and balance sheet are pressed onto the HDF base board by this machine to form the floor board, and this operation is conducted at high temperature and high pressure. Moreover, all kinds of beautiful patterns can be created on the boards with the help of the stainless steel press plate.

3. Floor cooling line: Large floor boards are cooled down quickly, and their edges are trimmed.

4. Cross cutter: It cuts a large floor board into two halves in the transverse direction.

5. Multi-blade saw: It further cuts the board into many smaller parts, and the final size should be in accordance with customer’s requirements.

6. Floor milling line: The milling machine makes grooves, namely clicks, around the floor board for installation.

7. Floor packing machine: It overlays a plastic film on the outer side of the packages.

The laminate flooring production line could deliver satisfying performance to customers, and it is highly recommended.

Production Scene

Links:https://www.globefindpro.com/products/61281.html

-

Water Cooled Diesel Generator Set

Water Cooled Diesel Generator Set

-

Safe

Safe

-

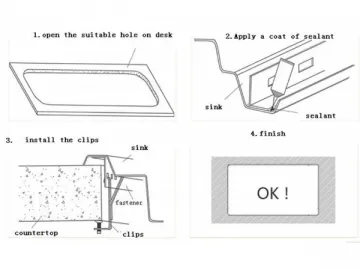

Topmount Single Bowl Sink

Topmount Single Bowl Sink

-

Garbage Bin

Garbage Bin

-

Kitchen Sink Selection Tips

Kitchen Sink Selection Tips

-

Safety Sign

Safety Sign

-

Gravure Printing Ink

Gravure Printing Ink

-

Eco-Friendly Water-Based Pigment Paste for Textile Printing and Dyeing

Eco-Friendly Water-Based Pigment Paste for Textile Printing and Dyeing

-

Letterpress Printing Ink

Letterpress Printing Ink

-

Multi-purpose Water-Based Pigment Paste

Multi-purpose Water-Based Pigment Paste

-

Solar Power Industry

Solar Power Industry

-

Construction Industry

Construction Industry