Better Physical Performance of the Prefabricated Track Surface

Compared with the polyurethane (PU) track surface, the prefabricated track surface has more superior physical properties

Endowed by the nature of rubber, the prefabricated track surface has obvious advantages over polyurethane track surface in tensile strength and elongation at break. The physical properties of the former can easily reach 2-3 times the value of the latter. The following is the performance comparison in tensile strength and elongation at break between them.

Excellent tensile property frees the prefabricated track surface from the cracking and delaminating trouble of the polyurethane track surface.

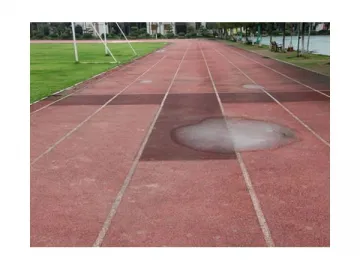

The prefabricated track surface is expected to be used for more than 10 years, which almost doubles the life of the polyurethane track surface. The following picture shows the broken polyurethane track that needs to be repaired after several years

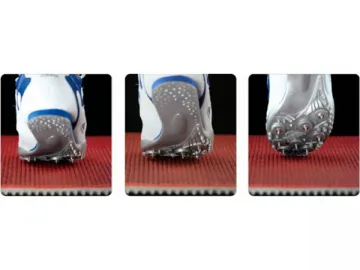

The pattern of the prefabricated track surface is more consistent than that of polyurethane track. It is durable over time and frequent use. The following picture shows the falling EPDM granules of the polyurethane track with an enlarged view

In a word, the polyurethane track requires more frequent maintenance and even replacement to keep it in use. Its costs on the labor, material, energy, time and space put both social and natural environment under great pressure. In comparison, the prefabricated track has much longer life, which better suits the sustainable development.

Links:https://www.globefindpro.com/products/61342.html

-

Superiorities of Tongxin Prefabricated Track Surfaces

Superiorities of Tongxin Prefabricated Track Surfaces

-

R&D Ability

R&D Ability

-

Highways

Highways

-

TSV Series Twin Screw Extrusion Equipment

TSV Series Twin Screw Extrusion Equipment

-

New Product Development

New Product Development

-

Plastic Recycling Line

Plastic Recycling Line

-

Motor Scooter

Motor Scooter

-

Furniture Board

Furniture Board

-

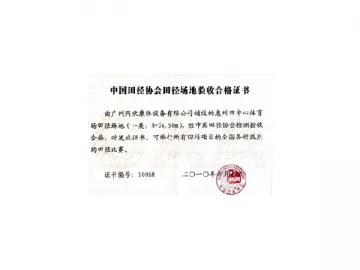

Worry-free Support in Site Acceptance

Worry-free Support in Site Acceptance

-

Rich and Optimized Product Lines

Rich and Optimized Product Lines

-

Rotary Tablet Press

Rotary Tablet Press

-

Win-Win System

Win-Win System