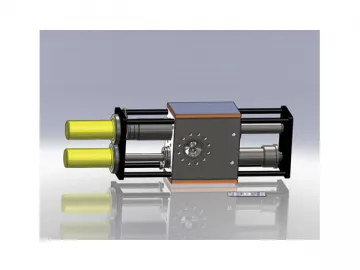

Fluoroplastic Compounding Line

Chuangbo has invested a lot of capital on the research of technique differences when handling different kinds of fluoroplastic. Now we have learned so much.

1. We have developed a series of twin screw extruders with more mature solution, including some specific parameters like screw speed, L/D ratio, torque level, for different kinds of fluoroplastic.

2. Chuangbo has developed and optimized the special screw element, and the quality of finished products is at the same level with its counterpart at abroad.

3. The improvement of anti-corrosion special type barrel structure makes the machine meet more production requirements. The optimized barrel structure and cooling technique has enhanced the machine’s effectiveness. Special sealing material and structure solution have been adopted for the main structure of the machine.

4. The main structure of the machine is made of Hastelloy C material. The heat stresses balance performance is great and material leakage-proof structure is well designed. Besides, the venting room’s structure is also improved.

5. The high torque technique and the whole production process are optimized for their better integration.

6. We have investigated the vacuum devolatilization technique and cooling method of the barrel, and then improved the vacuum system and the barrel cooling system.

7. The die head and die plate are manufactured according to new flow track design and optimized structure. We developed new type hot material pelletizing system.

8. New feeding system is researched and developed. The processing techniques have been investigated and optimized. A complete twin screw extruder product line is developed for fluoroplastic recycling. The performance is quite desirable, and has gained much appreciation from our widely spread clients. For example, we have been invited to upgrade 75 recycling lines for a company. After detailed communication, investigation, optimization, and tests, we increased the production capacity by 45% and improved the final products’ quality at a small cost, indicating the excellent performance of our advanced technologies.

TSH-35 fluoroplastic color master batch pelletizing

machine

TSH-52 test running machine exclusively for

fluoroplastic

TSH-75 water ring and air cooling pelletizing line for

the stabilization of F46 powder TSH-75 strand pelletizing line for the stabilization of

F46 powder TSH-85 strand pelletizing line for the stabilization of

F46 powder and PVDF

Links:https://www.globefindpro.com/products/61351.html