Reactive Extrusion Line

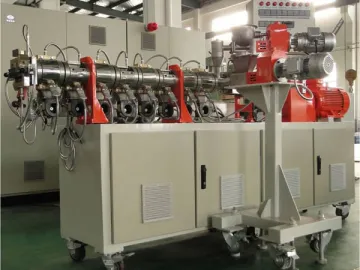

When dealing with a reaction system with high viscosity, twin screw extruder has overwhelming advantages due to its great heat and mass transfer performance, excellent interface renewing ability, narrow residence time distribution, large specific surface for devolatilization, and low threshold for continuous operation.

Twin screw polymerization extruder, or twin screw reactor, can be used for not only the heat transfer, mixing, shearing, conveying, venting and extrusion, but also polymerization reactions. So the processing techniques are more complicated and more technologies are involved. This kind of extruder is not frequently used but is of great importance. Different reaction types have different requirements for the extruder’s structure and parameters. Custom machine is usually needed for specific material system and polymerization technique.

Typical Application: TPU reactive extrusion (polyurethane fiber, elastomer and adhesive), PC melt phase polycondensation, PMMA bulk polymerization, acrylic resin polymerization, nylon polycondensation and different kinds of grafting reaction.

Reactive extrusion of TPU elastomer and the underwater pelletizer equipment

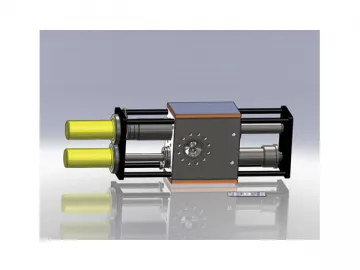

Standard high L/D ratio extruder for

reactive extrusion

TPU elastomer polymerization line

(TSB-85, L/D=56)

TPU polymerization and underwater

pelletizing (TSB-95, L/D=56)

TPU Spandex polymerization line

Explosion proof polymerization line

Links:https://www.globefindpro.com/products/61354.html