Nonwoven Fabric for Personal Care

Aside from advanced production lines for SMMS, melt blown and spunbond nonwoven fabric, we at GATHER Corporation also have a fully enclosed nonwoven material production workshop. These allow us to have an annual production capacity of 4000 tons.

Presently, we can supply our customers first-class SMS and spunbond nonwoven fabrics for use in personal care and personal hygienic product industries. With high hydrophilicity, super softness, great tear strength, or other features, our nonwovens are regularly applied in the production of sanitary napkins, disposable diapers, as well as incontinence pads. FDA approved raw materials ensure high safety.

We have set up specialized laboratories in each production workshop, so as to provide timely in-process control for each batch of product. Market oriented, our research and development team is able to develop useful and novel products frequently to meet ever-changing market demands. Our R&D capability always keeps ahead in our industry.

Following is a list of the main functions and features of our different range of nonwoven fabrics that used for personal care.

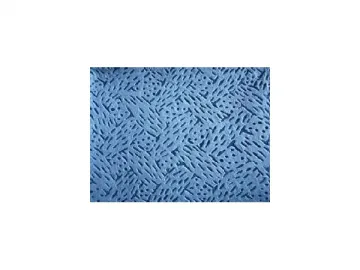

1. Laminated Nonwoven Fabric

It is the material for front waist band. It supports ultrasonic welding, and has high tensile strength. Different printing patterns are available, upon request.

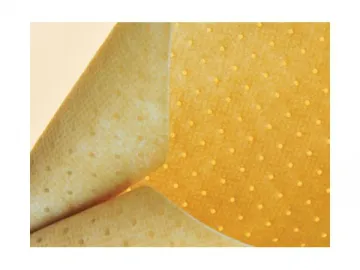

2. Elastic Nonwovens

This type of nonwoven material is used to make the left and right side waist bands of baby diapers and incontinence diapers, etc. While offering good tear strength, it is also soft and allergen-free.

3. 15gsm Hydrophilic Nonwoven Fabric

The hydrophilic material is a kind of widely used surface layer material for diapers and sanitary pads, because of its high absorbency and exceptional softness as well as greater tear resistance.

Basic Physical Properties

| Property | Unit | Lower limit | Target value | Ultra limit | Test Method |

| Basis weight | gsm | 14 | 15 | 16 | ASTM D 5035 |

| Machine Direction Tensile Strength | N/5cm | 28 | 32 | - | ASTM D 3776 |

| Machine Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Cross Direction Tensile Strength | N/5cm | 15 | 18 | - | ASTM D 3776 |

| Cross Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| 1st liquid-penetration time | s | - | 2 | 2.5 | EDANA 153.0 |

| 2nd liquid-penetration time | s | - | 3 | 3.5 | EDANA 153.0 |

| 3rd liquid-penetration time | s | - | 3.5 | 4.5 | EDANA 153.0 |

| Reversal-penetration quantity | g | - | 2 | 5 | EDANA 154.0 |

| Run-off quantity | g | - | 0 | 0.3 | EDANA 152.1 |

| Machine Direction Softness | mN | INDA IST 90.3 | |||

| Cross Direction Softness | mN | INDA IST 90.3 | |||

| Hygienic Standard | Conforms to GB15979-2002 hygienic standard for disposable personal care and personal hygienic products | ||||

4. 10gsm Spunbond Nonwovens

Our 10gsm spunbond nonwoven fabric made using FDA grade raw material is also an ideal solution for making the facing layer of personal care and personal hygienic products.

Basic Physical Properties

| Property | Unit | Lower limit | Target value | Ultra limit | Test Method |

| Basis weight | gsm | 9 | 10 | 11 | ASTM D 5035 |

| Machine Direction Tensile Strength | N/5cm | 15 | 20 | - | ASTM D 3776 |

| Machine Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Cross Direction Tensile Strength | N/5cm | 8 | 10 | - | ASTM D 3776 |

| Cross Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| 1st liquid-penetration time | s | - | 2 | 2.5 | EDANA 153.0 |

| 2nd liquid-penetration time | s | - | 3 | 3.5 | EDANA 153.0 |

| 3rd liquid-penetration time | s | - | 3.5 | 4.5 | EDANA 153.0 |

| Reversal-penetration quantity | g | - | 2 | 5 | EDANA 154.0 |

| Run-off quantity | g | - | 0 | 0.3 | EDANA 152.1 |

| Machine Direction Softness | mN | INDA IST 90.3 | |||

| Cross Direction Softness | mN | INDA IST 90.3 | |||

| Hygienic Standard | GB15979-2002 | ||||

5. 15gsm Super-soft Nonwovens

Our 15gsm super-soft nonwoven textiles are ideal backing material for baby diapers, sanitary napkins, and adult diapers. The exceptional softness can contact with skins directly while without causing itching or allergy.

Basic Physical Properties

| Property | Unit | Lower limit | Target value | Ultra limit | Test Method |

| Basis weight | gsm | 14 | 15 | 16 | ASTM D 5035 |

| Machine Direction Tensile Strength | N/5cm | 28 | 32 | - | ASTM D 3776 |

| Machine Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Cross Direction Tensile Strength | N/5cm | 15 | 18 | - | ASTM D 3776 |

| Cross Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Machine Direction Softness | mN | INDA IST 90.3 | |||

| Cross Direction Softness | mN | INDA IST 90.3 | |||

| Hygienic Standard | GB15979-2002 | ||||

6. 15gsm SMMS Nonwoven Fabrics

With high barrier property, our SMMS nonwoven fabric is often used to make the part that offers side-leakage prevention function for diapers and sanitary napkins.

Basic Physical Properties

| Property | Unit | Lower limit | Target value | Ultra limit | Test Method |

| Basis weight | gsm | 14 | 15 | 16 | ASTM D 5035 |

| Machine Direction Tensile Strength | N/5cm | 28 | 32 | - | ASTM D 3776 |

| Machine Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Cross Direction Tensile Strength | N/5cm | 15 | 18 | - | ASTM D 3776 |

| Cross Direction Elongation | % | 30 | 50 | - | ASTM D 3776 |

| Hydrostatic Pressure Protection Capacity | mm H2O | 150 | 180 | - | INDA IST 80.6 |

| Hygienic Standard | GB15979-2002 | ||||

As an experienced engineered fabric manufacturer, we can offer different types of nonwoven textiles for use in personal care industry. If you are interested in our products, we welcome you to visit our factory on-site. Nonwoven material samples are also available for your inspection and trial-use.

Links:https://www.globefindpro.com/products/61388.html