Luos

Luos has procured 23 sets of equipment from us till now.

Doush equipment in the factory of our client

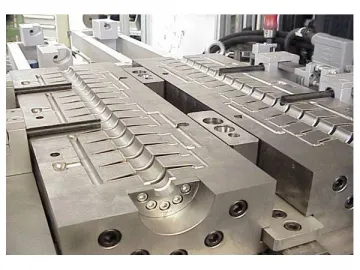

Doush provides them an integral solution, including the 250T rubber injection molding machine, 8-nozzle cold runner and 8-cavity mould for auto damper fabrication.

Final Result

1. The material utilization rate is improved to 96%.

2. The cycle time is reduced to 320 seconds.

3. The production efficiency is improved by 70%.

4. The unit cost is diminished by 1.17 CNY.

5. 494, 000 CNY cost is saved each year.

Luos 331A Project Inspection Report

Basic Information of Product

| Sizing amount | 162g | |

| Mould base type | Multiple layers, iron | |

| Quality requirement | Size, performance | |

| Current conditions | Output-shift: 295pcslow efficiency, lots of waste | |

| Expected goal | Output-shift: 436pcshigh efficiency, material waste reductionThe unit cost is reduced by more than 0.8 CNY. |

Comparison

| Original | Doush | Remark | |

| Machine T | Panshi/Huayi 300T | 250T series with variable pump | |

| Mould | 8 | 8 | |

| Cold runner | 8-nozzle | ||

| Cycle time (s) | 780 | 450 | |

| PCS/Hr | 37 | 64 | |

| PCS/8Hr | 295 | 512 | The efficiency is improved by 75%. |

| Runner (g) | 188 | 24 | 234g sizing material saved for each mould |

| Spure (g) | 30 | 0 | |

| Flashing (g) | 58 | 18 | |

| Sizing material waste (CNY/PCS, 25CNY/kg) | 0.86 | 0.13 | 0.73 CNY saved for each piece |

| Energy charge (CNY/shift) | 12×8×1=96 | 8×8×1=64 | |

| Energy charge (CNY/PCS) | 96/295=0.33 | 64/512=0.13 | 0.2 CNY saved for each piece |

| Worker salary apportion (100CNY/shift) | 100/295=0.34 | 100/512=0.2 | 0.14 CNY saved for each piece |

| Post processing (deflashing, drilling, etc.) (CNY) | 0.1 | 0 | 0.1 CNY saved for each piece |

| Equipment apportionCNY/(6600Hr/year) | (30000 50000)/10/6600/37=0.14 | (470000 120000)/10/6600/64=0.14 | |

| Total manufacturing cost (CNY/PCS) | 1.77 | 0.6 | 1.17 |

Conclusion

1. Each piece of product saves 1.17 CNY and the annual output is 6600×64=422400PCS, so, there are 494,208 CNY costs are saved in total.

2. The project result is beyond the expectation, thus meeting the demands of Luos.

| Existing Brand | Doush | |

| Runner | ||

| Ruffles with uneven thickness are formed and cannot be removed. | Each product comes with 3g injection residuals that can be rapidly removed by tools. | |

| Sprue | No pictureGenerally, the injection volume should be 30g more than that the sprue can contain. | No picture |

| Flash | ||

| The flashes are bonded together and can be removed in flake shape during demoulding. Each mould comes with 58g flashes. | Each mould has 18g flash residuals. | |

| Deflashing 1 | ||

| The flashes at the parting line should be removed by scalpel. | No flash at the parting line | |

| Deflashing 2 | ||

| The shear is used to remove the flashes at the edge and center of moulds. | The flashes at the edge and center of moulds can be directly torn down by hands. This work can be finished by vulcanization workers and does not need post processing. | |

| Drilling | ||

| Drilling and cleaning are required for screw installation. | Cleaning is not needed. |

Links:https://www.globefindpro.com/products/61531.html