Komatsu Undercarriage Parts

A complete array of undercarriage parts can be assembled together to act as a powerful system, so as to guide crawler equipment over all types of terrains. As an experienced construction equipment parts designer and manufacturer in this industry, we aim to help our clients attain the maximum benefits from our undercarriage components. According to our statistics, the undercarriage system account for half of the crawler equipment’s cost. Therefore, correct selection, proper maintenance, and timely replacement of undercarriage parts are the key factors to save users operational cost.

Over the past two decades, we have been specialized in the supply of Komatsu undercarriage parts. All our Komatsu excavator parts and bulldozer parts are designed and manufactured in strict conformation with original manufacturer specifications, and they are classified into over 200 models to satisfy clients’ every demand. We can offer Komatsu parts with the most complete range of specifications in China. To illustrate, available Komatsu undercarriage parts include the track roller, top roller, sprocket, idler, track chain, hydraulic cylinder, and more.

We have separate workshops responsible for processes such as mold making, casting, forging, heat treatment, machining, and assembly. While reducing production cost, the in-house production also enables us to easily control the management cost and product quality. Thus, our Komatsu undercarriage parts are offered at competitive prices and with reliable performance.

Track Roller

Komatsu track rollers offered by CJMC are manufactured using special steel materials, and are ideal replacement of original equipment parts. They have high surface hardness and rationally distributed hardness layer, and meanwhile, they wear at a balanced rate. These ensure long service life.

We can offer both single and double flange track rollers for use on Komatsu bulldozers, crawler loaders, and harvesters. Additionally, we also offer customized Komatsu undercarriage parts according to customers' demands. OEM service is provided as well.

Available Models

| PC10 | PC60-1/D20 | PC150-1/5 | PC280-3 |

| PC30 | PC60-5/6 | PC200-1 | PC300-3 |

| PC40 | PC80 | PC200-3 | PC300-5/6 |

| PC50-2 | PC100/PC100-3 | PC200-5/6 | PC400-3/5 |

| PC50-3 | PC120 | PC220-3/7 | PC450-6 |

| PC60-5/6 | PC120-1/2/3/4/5/6 | PC240-3 |

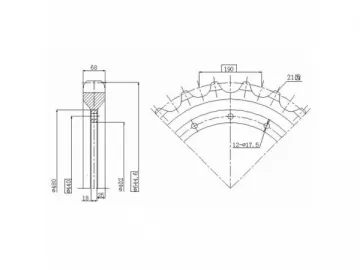

Top Roller

We adopt special steel materials for making Komatsu top rollers. Through analysis, it is proven that our carrier roller has long lifespan due to its high surface hardness, rational hardness distribution, as well as superior wearing resistance.

Available Models

| PC40 | PC60 | PC60-5/6 | PC60-7 | PC60L-5 |

| PC80-1/3 | PC90-1 | PC100-2/3/5 | PC120-2/3/5 | PC200-2/3/5 |

| PC200-7 | PC200-8 | PC200-3/5/6 | PC240-3/5 | PC300 |

| PC300-5 | PC400 | PC400-7 | D60 |

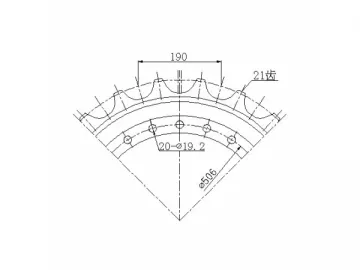

Sprocket

Our range of PC100-5 Komatsu sprocket is interchangeable with PC120-5, PC120-6, and PC100-6 series products. Made using special steel material, this range of Komatsu undercarriage part is machined according to international standard, and undergoes special heat treatment to offer high surface hardness and long wear life.

In addition to available standard models, we can also customize Komatsu sprockets based on client-side specifications. OEM service is available as well.

Available Models

| PC40-7 | PC50 | PC60/PC60-3/5 | PC60-6 | PC100-3 |

| PC120-3 | PC100-6F | PC120-5/6 | PC100-5/6 | PC200-1/2/3 |

| PC200-5/6/7 | PC300-3/5 | PC300-6 | PC400-3/5 | PC400-6 |

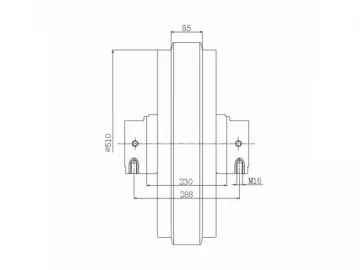

Idler

Our range of Komatsu idler is made of special steel material and is machined in strict conformation with international standard. Through special heat treatment as well as medium-frequency hardening and tempering, the Komatsu idler offers smooth surface, high surface hardness, and good wearing resistance. These contribute to long lifetime.

Available Models

| PC20 | PC30 | PC40 | PC60 | PC100/PC120 |

| PC180 | PC200-1/2 | PCPC200-3 | PC200-5/6 | PC200-7 |

| PC240 | PC300-1/3 | PC300-5/6 | PC400/PC400-5/6 | PC450 |

| D85 |

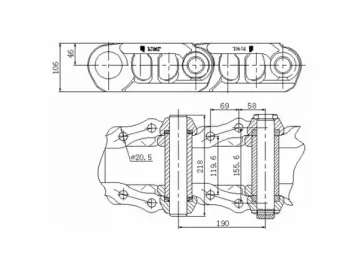

Track Chain

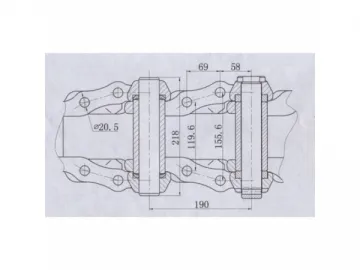

Model: PC100-3

Material: 45Mn2

Quality: Through integral quenching and tempering, the link plates are provided with optimized mechanical performances and offer integral hardness from HRC27 to 34. Afterwards, they are further heat treated to create a hardening layer with depth from 5 to 8mm. This also ensures surface hardness between HRC47 and 55.

Color: Black

Technique: Forging

Weight: 300kg

Specifications: 42 links

Certificate: ISO9002

MOQ: Unlimited

Warranty: 1800 working hours

Deliver cycle: 30 working days after order confirmation, or depend on the order quantity

Payment terms: D/L, D/P, T/T 30% in advance, and the balance should be paid before delivery

Available Komatsu Track Chain Models

| PC60-5 | PC60-6 | PC100-5 | PC200-3 |

| OC200-5 | PC300-1 | PC300-2 | PC300-3 |

| PC300-5/6 | D60 | D31 | D20 |

Links:https://www.globefindpro.com/products/61621.html

-

Galvanized Steel Sheet as Building Material

Galvanized Steel Sheet as Building Material

-

Cold Rolled Steel Sheet as Construction Material

Cold Rolled Steel Sheet as Construction Material

-

Cold Rolled Steel Sheet as Car Body Panels

Cold Rolled Steel Sheet as Car Body Panels

-

Volvo Undercarriage Parts

Volvo Undercarriage Parts

-

Illuminated Mirror Product

Illuminated Mirror Product

-

Hyundai Undercarriage Parts

Hyundai Undercarriage Parts

-

LED Spot Lights

LED Spot Lights

-

Daewoo Undercarriage Parts

Daewoo Undercarriage Parts

-

Color Coated Steel Sheet as Interior Decoration Material

Color Coated Steel Sheet as Interior Decoration Material

-

Sumitomo Undercarriage Parts

Sumitomo Undercarriage Parts

-

Caterpillar Undercarriage Parts

Caterpillar Undercarriage Parts

-

Hitachi Undercarriage Parts

Hitachi Undercarriage Parts