CNC Corner Cleaning Machine

1. Function

The CNC corner cleaning machine is designed for cleaning fillet welds of PVC doors and windows.

2. Features

1) The product has added a corner cleaning monitoring system, in order to synchronously observe the cleaning process, which conduces to programming.

2) The imported numerical control system improves reliability.

3) Due to dedicated main shaft for milling, it can process accurately.

4) The milling motor is installed overhead to make sure that the CNC corner cleaning machine has stable processing properties.

5) Its error compensation in dimension brings about high precision.

6) The operator may set machining programs for over 60 kinds of profiles. Furthermore, the oblique and circular interpolation function helps the machine to clean fillet welds of various profile sections.

3. Main Technical Parameters

Input power supply: 380/220V 50Hz

Power: 1.7kW

Rotational speed of motor: 2800r/min

Working air pressure: 0.5~0.8MPa

Air consumption: 60L/min

Height of cleanable profile: 30~120mm

Width of cleanable profile: 20~120mm

Dimension: 2000mm×1820mm×1500mm

Weight: 700kg

Related Names

Door Angle Seam Cleaner | Window Cleaning Equipment | Profile Surface Smoother

Links:https://www.globefindpro.com/products/61718.html

-

Four Point Multi-Layer Parallel Welding Machine

Four Point Multi-Layer Parallel Welding Machine

-

NDW Series Computerized Torsion Testing Machine

NDW Series Computerized Torsion Testing Machine

-

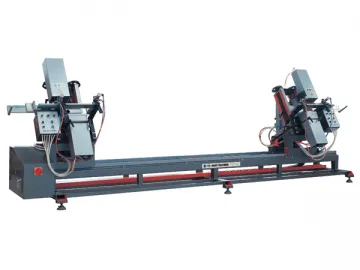

LJZ2A-450×3600 Double Mitre Saw

LJZ2A-450×3600 Double Mitre Saw

-

Vacuum Absorption Wood Router

Vacuum Absorption Wood Router

-

Precise Double Mitre Saw with Digital Measurement Display

Precise Double Mitre Saw with Digital Measurement Display

-

XJJ Series Simple Beam Impact Testing Machine

XJJ Series Simple Beam Impact Testing Machine

-

Electronic Broaching Machine for Impact Test

Electronic Broaching Machine for Impact Test

-

Lock-hole Processing Machine

Lock-hole Processing Machine

-

Corner Cleaning Machine

Corner Cleaning Machine

-

Double-head Water-slot Milling Machine

Double-head Water-slot Milling Machine

-

PVC Profile Four Head Seamless Welding Machine

PVC Profile Four Head Seamless Welding Machine

-

MWW Series Computerized Wood-based Panel Universal Testing Machine

MWW Series Computerized Wood-based Panel Universal Testing Machine