WAW-G Series Computerized Electro-hydraulic Servo Universal Testing Machine

1. Equipment Usage

The WAW-G series computerized universal testing machine is provided with electro-hydraulic servo. It is designed for tensile, compression, bend and shear test on metallic or non-metallic materials. The product is ideal for bending or compression test on bricks, and tensile, compression or bending test on rebar. It can be employed in aviation material testing, construction quality testing, colleges, industrial and mining enterprises, R&D institutions, and other fields. The test operation and data handling abide by GB228.1-2010 "Standard Test Methods for Tension Testing of Metallic Materials at Room Temperature", and other GB or ISO test standards.

2. Main Technical Parameters of Electro-hydraulic Servo Universal Testing Machine

| Model | Specification | WAW-1000G | WAW-2000G | ||

| Maximum testing force | 1000 | 2000 | ||

| Measurement range of testing force | 2%~10%FS, full scale consists of 1, 2, 5 and 10 gear | |||

| Relative error of testing force indicating value | ≤0.5% indicating value | |||

| Measurement resolution of displacement (mm) | 0.005 | |||

| Accuracy of deformation measurement | ±0.5%FS | |||

| Control range of stress rate | 1MP/S-60MP/S | |||

| Adjustable range of test strain rate | 0.00025/S-0.0025/S | |||

| Control range of displacement rate | 0.1mm /min-60mm/min | |||

| Control range of keeping force, deformation and displacement | 0.3%~100%F.S | |||

| Test space (mm) | Tensile | 650 | 620 | |

| Compression | 580 | 550 | ||

| Inside width of space | 500 | 530 | ||

| Dimension of upper and lower platens (mm) | 210×210 | φ240 | ||

| Maximum stroke of piston (mm) | 250 | |||

| Power supply | 380V±10%,50Hz | |||

| Working environment | 10 ℃ ~30℃, relative humidity ≤80% | |||

| Dimension (L×W×H) ( mm) | Main engine | |||

| Control cabinet | ||||

| Weight (kg) | 4500 | 5000 | ||

3. Key Features

1) Load Measurement

The electro-hydraulic servo universal testing machine adopts the high-precision load cell and hydro-cylinder piston to ensure great precision, high reliability, good linear repeatability, strong shock resistance, high stability and long service life.

2) Displacement Measurement

The imported optical-electricity encoder is praised for high accuracy and reliability.

3) Deformation Measurement

The used strain extensometer comes with high precision, stable performance and reasonable price.

4) Automatically Clamping

Because of an independent hydraulic power supply for clamping, the product may automatically, firmly and safely clamp materials.

5) Multiple Protection

It is provided with not only the software and hardware double protection, but also the piston stroke mechanical and electric double protection. Once the maximum load is exceed by 2~10%, safety protection will take effect.

6) Auto-calibration

The electro-hydraulic servo universal testing machine can automatically calibrate load, deformation and displacement.

7) Test result calculating

ReH, ReL, Fm, Rp0.2, Rt0.5, Rm, E and other test results can be automatically calculated in accordance with your demands.

8) Various Control Methods

a) Force, displacement and deformation three-closed-loop control

b) Multi-step stored program control, including tension test of metallic materials

c) The software for professional users, namely, control program editor

d) You can also customize specific control program on the basis of your needs.

Related Names

Metal Fatigue Tester | Mechanical Testing Machine | Servo Metal Tester

Links:https://www.globefindpro.com/products/61803.html

-

V Corner Cleaning Machine

V Corner Cleaning Machine

-

Dropping Ball Impact Testing Machine

Dropping Ball Impact Testing Machine

-

WLW Series Horizontal Tensile Testing Machine

WLW Series Horizontal Tensile Testing Machine

-

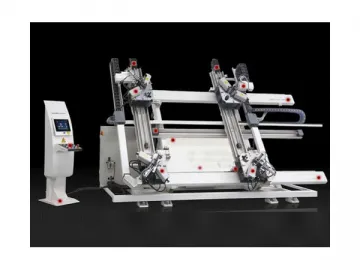

Aluminum Door Window Four Head Automatic Corner Crimping Machine

Aluminum Door Window Four Head Automatic Corner Crimping Machine

-

T Locking Plate I

T Locking Plate I

-

Proximal Humeral Locking Plate II Type

Proximal Humeral Locking Plate II Type

-

Distal Medial Tibial Locking Plate

Distal Medial Tibial Locking Plate

-

Full-load Test Platform

Full-load Test Platform

-

Single Head Variable Angle Welding Machine

Single Head Variable Angle Welding Machine

-

Reconstruction Locking Plate

Reconstruction Locking Plate

-

5.0mm Proximal Lateral Tibial Golf Locking Plate

5.0mm Proximal Lateral Tibial Golf Locking Plate

-

Special Testing Machine

Special Testing Machine