Tetrabromobisphenol A Bis, Dibromopropyl Ether / BDDP

| Tetrabromobisphenol A Bis (2, 3-Dibromopropyl Ether) (FR-BDDP) | |

| Equivalent Brand | PE-68, Saytex HP800, FR-720, FG-3100, bromkal 66-8 |

| Molecular Formula | C21H20Br8O2 |

| Molecular Weight | 943.2 |

| CAS No. | 21850-44-2 |

| Abbriviation | TBBPA-DBPE |

Main Specifications

| Item | Specifications |

| Appearance | White Powder or Granular |

| Whiteness | 92 Min. |

| Bromine Content | 67% Min. |

| Melting Point | 105-115℃ Min. |

| Volatility | 0.30% Max. |

Features and Applications

1. Tetrabromobisphenol A bis (2, 3-dibromopropyl ether) can be abbreviated to TBBPA-DBPE, which is also known as FR-BDDP or BDDP. With ultra high heat and light stability, it is a great additive flame retardant for polyolefins and polymers including PP, HDPE, and LDPE.

2. Moreover, this brominated compound is an ideal polyurethane foam additive which is often used in the manufacturing of PU foam goods with high density structure. It shows nice compatibility with polyether polyols, and helps lower the viscosity of combined polyether polyols.

3. Tetrabromobisphenol A bis (2, 3-dibromopropyl ether) is especially appropriate for the filling of complex-structure carved mould in structural foam and furniture industry. It can not only make construction more convenient, but also significantly increase the qualification rate of our product. The experience of users indicates that the requirements of different flame-retardant ratings can be achieved by adding the dosage of TBBPA-DBPE ranging from 8-18%.

4. Additionally, this brominated flame retardant can be also used together with other inorganic flame retardants, so as to further save the production costs and optimize the manufacturing technique. Thus, our product provides low toxicity, low smoke, and high fire resistance.

5. Similarly, tetrabromobisphenol A bis(2, 3-dibromopropyl ether) can offer a wonderful fire resistance performance, when added into the unsaturated polyester resin (UPR) and furan resin.

6. Our Tetrabromobisphenol A bis (2, 3-dibromopropyl ether) can be directly added into the combined polyether, and then be blended uniformly. It had better be used immediately after being mixed well.

Applied Formulations

| Homo-PP | Co-PP | Homo-PP | Co-PP | |

| 98.0% | 98.0% | 84.0% | 80.3% | |

| FR-BDDP | 1.50% | 1.50% | 12.0% | 14.5% |

| Sb2O3 | 0.50% | 0.50% | 4.00% | 5.2% |

| UL94 (1.6mm) | V2 | V2 | V0 | V0 |

| UL94 (3.2mm) | -- | -- | -- | -- |

Product Application Display

| PP Fan | Car Bumper |

Links:https://www.globefindpro.com/products/62008.html

-

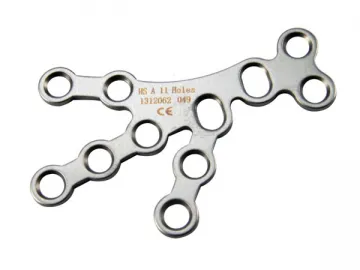

S-clavicle Plate IV

S-clavicle Plate IV

-

Distal Lateral Fibular Plate

Distal Lateral Fibular Plate

-

Small Oblique T-plate

Small Oblique T-plate

-

One Third Tubular Plate

One Third Tubular Plate

-

3-Hydroxyphenylphosphinyl-Propanoic Acid, CEPPA

3-Hydroxyphenylphosphinyl-Propanoic Acid, CEPPA

-

Distal Medial Femoral Plate, Condylar Plate

Distal Medial Femoral Plate, Condylar Plate

-

I Model Calcaneal Plate

I Model Calcaneal Plate

-

Tris, Tribromoneopentyl Phosphate / TTBNP

Tris, Tribromoneopentyl Phosphate / TTBNP

-

Tris, 2,3-Dibromopropyl Isocyanurate / TBC

Tris, 2,3-Dibromopropyl Isocyanurate / TBC

-

I Model Ulna Plate / Olecranon Plate

I Model Ulna Plate / Olecranon Plate

-

Distal Lateral Femoral Condylar Plate II

Distal Lateral Femoral Condylar Plate II

-

4.5mm Distal Medial Tibial Plate

4.5mm Distal Medial Tibial Plate