Jet Mill

Working Principle

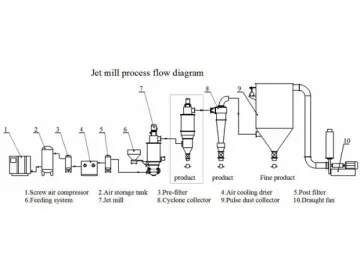

The AB jet mill is a dry grinding machine that makes use of the high speed jet air to grind various materials into ultrafine particles. After being filtered and dried, the compressed air will pass through a series of supersonic nozzles and enter the grinding cavity where the materials will get accelerated to impact, crash each other and be smashed at the intersection of the nozzles.

Then the powdered materials will be graded timely by the classifier in the upper part of the machine. The coarse particles will be rejected by classifying wheel and go back to the mill again, while the qualified particles will be collected by the cyclone collector.

Product Features

1.The particles grinded by our jet mill are even in size with a high degree of fineness (Min.D97=2um).

2. The vortex classifier can grade the resultant powder in time to prevent excessive pulverization.

3. The product is powered by the compressed air, which will expand at the outlet of nozzles to keep low operating temperature in the grinding process. Therefore, it is suitable for processing the materials with heat sensitivity and low melting point.

4. This jet mill is free from any impurity during grinding, getting the smashed materials with high purity.

5. There is no rotating part in the grinding chamber so that the product works with little mechanical abrasion, as well as low operating noise.

6. With compact structure, it is space saving and easy for installation and dismantlement.

7. The inflammable and explosive material can be grinded in a closed cycle via the inert gases, which is the working media and can be recycled. The consumption of the inert gases is minimized.

8. Due to the high automation, this product is convenient for operation.

Application

The jet mill is widely applied in the superfine grinding of various dry powdered materials, such as chemicals, pharmaceutical, metallurgy materials, abrasives, non-metallic minerals, battery anode and cathode materials, talc, kaolin, quartz, graphite, flame retardant, ceramics, etc.

AB Jet mill Technical Parameters

| Item/Specification | AB03 | AB06 | AB10 | AB15 | AB20 | AB30 | AB40 | AB60 | AB80 |

| Production capacity(kg/h) | 10-100 | 20-250 | 60-500 | 150-800 | 200-1200 | 300-1800 | 400-2500 | 600-3500 | 1000-5000 |

| Air consumption (m3/min) | 3 | 6 | 10 | 15 | 20 | 30 | 40 | 60 | 80 |

| Size of feed material (mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

| Product fineness (d50=μm) | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 | 0.5-150 |

| Installed power (kw) | 30 | 50 | 90 | 110 | 150 | 220 | 300 | 450 | 580 |

Jet Mill Process Flow Diagram

Nitrogen Protection Jet Mill Process Flow Diagram

Related Names

Fluidized Bed Grinding Machine | Jet Pulverizer Manufacturer | Powder Processing Equipment

Links:https://www.globefindpro.com/products/62216.html

-

RPCF Series Automatic Reactive Power Compensation Controller

RPCF Series Automatic Reactive Power Compensation Controller

-

Automatic Reactive Power Compensation Controller

Automatic Reactive Power Compensation Controller

-

Particle Dry Cleaning Machine

Particle Dry Cleaning Machine

-

Ultra-fine Roller Mill

Ultra-fine Roller Mill

-

PU2000 Home Energy Saver

PU2000 Home Energy Saver

-

Double Insulated Sleeve

Double Insulated Sleeve

-

CJX8C Series AC Capacitor Switching Contactor

CJX8C Series AC Capacitor Switching Contactor

-

Ball Mill

Ball Mill

-

Intelligent Capacitor Bank

Intelligent Capacitor Bank

-

Power Inverter

Power Inverter

-

Aramid Reinforced Epoxy Wound Tube

Aramid Reinforced Epoxy Wound Tube

-

Electrical High Voltage Insulated Sleeving

Electrical High Voltage Insulated Sleeving