Superfine Impact Mill

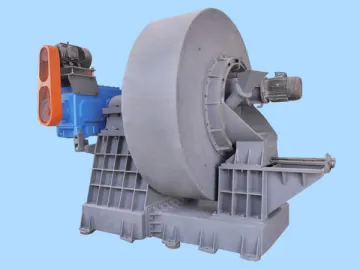

The CR superfine impact mill is developed and optimized on the basis of the similar domestic and foreign products, combined with our years of practical experience in this field. Integrating the unique crushing mechanism with advanced grading technology, this versatile equipment achieves excellent performance in grinding, classifying, shaping and depolymerizing the material with Mohs hardness less than 3 degree.

Working Principle

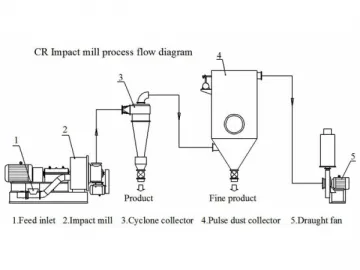

By the quantitative feeder, the materials will be fed into the grinding chamber where they will get sheared and smashed drastically through colliding with high speed rotor and stator with inlaid toothed lining plate. The resultant powder will subsequently be classified in time. The qualified powder will be collected by special device in the subsequent process while the coarse particles will be recycled for further milling.

Product Features

1.With the integration of mill and classifier, the superfine impact mill get the fine powder that is free of over grinding.

2. The unit enjoys a narrow particle size distribution and adjustable fineness ranging from (d97) 2μm to 100μm.

3. The airflow inside the unit is good for reducing the temperature, making it suitable for smashing the materials that are sensitive to heat.

4. The totally enclosed negative pressure system allows for dustless operation.

5. This product is available for dispersing and depolymerizing the agglomerate materials.

6. It is equipped with slag discharge device, which can automatically discharge the hard material and impurities in the grinding chamber.

7. The product occupies a small area due to the simple and compact structure.

8. Few wearing parts are applied and it allows for easy maintenance.

Application

The superfine impact mill is suitable for grinding a wide variety of dry materials including flake, acicular, fibrous material with Mohs hardness below 3 degree and moisture content below 15%. It is also available in dispersing and classifying the dried nonmetal mineral powder made in wet process. Its principal applications lie in the field of chemical, pharmaceutical, food, catalyst, aluminum hydroxide, aluminum oxide, talc, mica, graphite, AC foaming agent, petroleum coke, pesticide, dye, paint, carbon black, printing, electronic material, etc.

Technical Parameters

| Type | CR600 | CR800 | CR1000 | CR1200 | CR1600 |

| Feeding size(mm) | <15 | <15 | <15 | <15 | <15 |

| Smashing fineness(D97=μm) | 2-180 | 2-180 | 2-180 | 2-180 | 2-180 |

| Handling capacity (t/h) | 0.1-2 | 0.3-3 | 0.5-5 | 0.8-8 | 1.2-12 |

| Power (kw/h) | 22-45 | 45-55 | 55-75 | 75-132 | 132-160 |

CR Impact Mill Process Flow Diagram

Related Names

Powder Grinder for Sale | Ultrafine Grinding Mill | Powder Processing Device

Links:https://www.globefindpro.com/products/62232.html

-

PU3500&4500 Industrial Energy Saver

PU3500&4500 Industrial Energy Saver

-

JK-8CK(H) Series Intelligent Low Voltage Reactive Power Compensation Controller

JK-8CK(H) Series Intelligent Low Voltage Reactive Power Compensation Controller

-

BGMJ Series Low Voltage Shunt Capacitor, Power Capacitor

BGMJ Series Low Voltage Shunt Capacitor, Power Capacitor

-

Test Center

Test Center

-

Disc Type Jet Mill

Disc Type Jet Mill

-

Grain Grinding and Shaping Machine

Grain Grinding and Shaping Machine

-

Low Voltage Series Reactor

Low Voltage Series Reactor

-

RPCF3 Series Automatic Three Phase Reactive Power Compensation Controller

RPCF3 Series Automatic Three Phase Reactive Power Compensation Controller

-

Induction Heating Capacitor

Induction Heating Capacitor

-

CJ19 Series AC Capacitor Switching Contactor

CJ19 Series AC Capacitor Switching Contactor

-

JHM Ball Mill

JHM Ball Mill

-

High Temperature Lithium Battery Sleeve

High Temperature Lithium Battery Sleeve