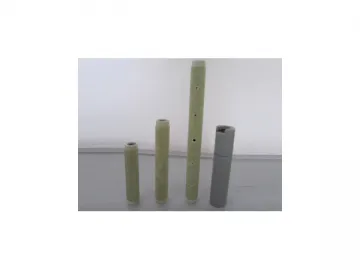

Self-lubricating Bushing

1. Our self-lubricating bearing requires no lubricating oil or small amount of lubricant, ideal for occasions where there is no lubricant to refill or it is difficult to add lubricant. When using, it needs no or less maintenance.

2. It can operate at a temperature range of -195℃~ 280℃.

3. This product comes with high abrasion resistance, low friction coefficient, good running-in performance, as well as a long service life. In addition to this, it has a pack of features such as dimensional stability, low coefficient of thermal expansion, and high heat dissipation efficiency.

4. It generates no pollution and produces low noise.

5. With the thin-walled design, this product is lightweight and this design contributes to reducing its size.

6. It is capable of creating transfer film to protect the shaft during the operation process.

7. Our product supports using with shafts that are not quenched or tempered. Therefore, the processing difficulty of shafts can be greatly lowered.

8. The surface of steel could be electroplated with various metal materials, so our steel self-lubricating bushing can be used in an environment with corrosive medium.

The self-lubricating bearing or bushing is widely used for sliding parts of various machinery such as automated machinery (like telescopic, rocking, sliding, bending, turning, or rotary parts), hydraulic cylinder guide sleeve, textile machine, vending machine, plastic injection machine, die-casting equipment, rubber manufacturing machine, fitness equipment, office facilities, as well as hydraulic carrying vehicle.

Technical Specifications

Chemical Performance Parameters

| Alcohol | Resistibility | Saline | Resistibility |

| Methanol | Y | Sodium Acetate | Y |

| Ethanal | Y | Sodium Carbonate | Y |

| Allyl | N | Ammonium Nitrate | Y |

| Butyl | N | Ammonium Chlorate | Y |

| Propyl | Y | Magnesium Sulfate | Y |

| Hydroxy acetone | Y | Gas | |

| Solvent | Butane | Y | |

| Acetone | Y | Ozone | Y |

| Toluene | Y | Nitrogen | Y |

| Methyl Ethyl Ketone | Y | Natural Gas | Y |

| Trichloro Ethylene | N | Ethyne | Y |

| Benzene | N | Hydrogen | Y |

| Acid (10%) | Fluorin | N | |

| Hydrochloric Acid | Y | Chlorine | N |

| Boracic Acid | Y | Alkali (10%) | |

| Acetic Acid | Y | Sodium Hydroxide | Y |

| Sulfuric Acid | Y | Calcium Oxide | N |

| Nitric Acid | N | Aluminum hydroxide | Y |

| Carbonic Acid | N | Others | |

| Hydrofluoric Acid | N | Freon | Y |

| Oil | Carbinol | Y | |

| Gear Oil | Y | Sodium Nitrate | Y |

| Engine Oil | Y | Ethanediol | Y |

| Hydraulic Oil | Y | Ammonia | N |

| Linseed Oil | Y | Boiling Water | N |

| Fuel | |||

| Gasoline | Y | ||

| Jet Fuel | Y | ||

| Diesel Oil | Y | ||

| Petroleum | Y | ||

| Sodium Hydroxide | Y |

Technical Parameters

| Description | Unit | Parameter | |

| Max. Load | Static Load | MPa | 240 |

| Dynamic Load | MPa | 160 | |

| Density | G/cm3 | 2.00 | |

| Max. Sliding Linear Speed | m/s | 0.20 | |

| Max. PV Value | MPa.m/s | 2 | |

| Friction Coefficient (Dry) | — | 0.03-0.12 | |

| Continuous Operating Temperature | °C | -120-180 | |

| Instantaneous Operating Temperature | °C | -120-230 | |

| Lubricating Layer | — | Special Fiber PTFE Fiber Lubricant | |

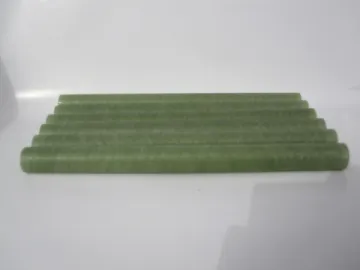

| Support Layer | — | Epoxy resin with fiberglass wound | |

| Typical Application | — | 1. Oil Cylinder Axle Sleeve | |

| 2. Arm Bushing for Construction Machinery | |||

| 3. Cranes, Material Handling Equipment | |||

| 4. Machinery Used at Harbor | |||

| 5. Packaging Machine | |||

Product Testing Report

| Class F1 Test Report in French-01 | Class F1 Test Report in French-02 | Class F1 Test Report in French-03 | Class F1 Test Certificate in French-01 |

| Class F1 Test Report in English-01 | Class F1 Test Certificate in English-01 | Class I2 Test Report in French-02 | Class I2 Test Report in French-03 |

| Class I2 Test Certificate in French-01 | Class I2 Test Report in English-02 | Class I2 Test Report in English-03 | Class I2 Test Certificate in English-01 |

Links:https://www.globefindpro.com/products/62246.html

-

Epoxy Glass Cloth Laminated Tube / Pipe

Epoxy Glass Cloth Laminated Tube / Pipe

-

Magnetic Bar Sleeve

Magnetic Bar Sleeve

-

Phenolic Paper Laminated Tube

Phenolic Paper Laminated Tube

-

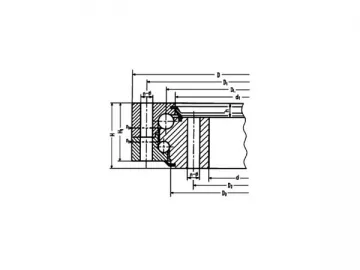

Cross-Roller Slewing Bearing

Cross-Roller Slewing Bearing

-

Four-Point Contact Ball Slewing Bearing(External gear)

Four-Point Contact Ball Slewing Bearing(External gear)

-

Fiberglass Reinforced Epoxy Resin Wound Pipe

Fiberglass Reinforced Epoxy Resin Wound Pipe

-

Double Row Ball Slewing Bearing(Without gear)

Double Row Ball Slewing Bearing(Without gear)

-

Wind Turbine Main Shaft Bearing

Wind Turbine Main Shaft Bearing

-

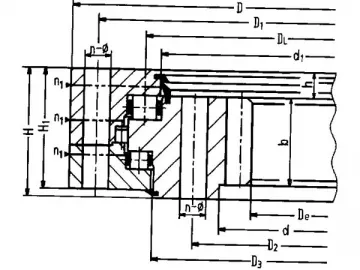

Three-Row Roller Slewing Bearing (Internal gear)

Three-Row Roller Slewing Bearing (Internal gear)

-

Arc Extinction Tube / Arc Suppression Pipe

Arc Extinction Tube / Arc Suppression Pipe

-

Slewing Bearing

Slewing Bearing

-

High Voltage Shunt Capacitor

High Voltage Shunt Capacitor