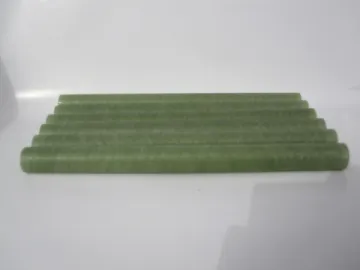

Fiberglass Reinforced Epoxy Resin Wound Pipe

Our fiberglass reinforced epoxy resin wound pipe is commonly used in the manufacturing of electrical equipment structural components like fuse protector, on-load tap changer, transformer, lightning arrestor, electric reactor, and 110KV~ 1000KV composite hollow insulator, just to name a few. Its performance meets the IEC standards. This twining tube is made from non-alkali glass fibers as well as epoxy resin using a cross-winding method. In addition, we can offer products with a complete range of specifications to suit individual clients' needs.

Technical Data

| No. | Property | Unit | Data |

| 1 | Axial compressive strength | Mpa | 157 |

| 2 | Water absorption | % | 0.02 |

| 3 | Density | g/cm3 | 1.90 |

| 4 | Relative permittivity (50HZ) | 5.02 | |

| 5 | Dielectric loss factor (50HZ) | 3.1* 10 -3 | |

| 6 | Withstand voltage along the surface after becoming damp (12KV,5 minutes) | No surface flashover, no puncture | |

| 7 | Adhesive strength between layers | Mpa | 649 |

| 8 | Vertical layer electrical strength (in oil at 90 ºC, specimen thickness: 2.6mm ) | MV/m | 21.2 |

| 9 | Parallel layer breakdown voltage (in oil at 90 ºC ) | KV | 44.7 |

| 10 | Insulation resistance after immersion in water | Ω | 3.5* 10 13 |

| 11 | Winding angle | degrees | ±50 ~55 (customizable) |

| 12 | Fiber content (weight ratio) | 70 ~ 75% | |

| 13 | Axial coefficient of thermal expansion | 1.8 E-05 1/K | |

| 14 | Glass transition temperature | ℃ | 110 ~120 |

| 15 | Chemical resistance (mineral oil) | excellent | |

| 16 | Solvent and diluted acid resistance | good | |

| 17 | Axial elastic modulus | Mpa | 14000 |

| 18 | Tensile strength (axial/ radial) | MPa | 280MPa/600MPa |

| 19 | Axial flexural or bending strength | MPa | 350 |

| 20 | Shear strength | MPa | 150 |

| 21 | Magnitude of partial discharge | ≤5 | |

| 22 | Dielectric strength (axial/ radial) | kV/mm | 3~6 kV/mm / 10~12 kV/mm |

| 23 | Lighting impulse withstand voltage | KVP | 110 |

| 24 | Power frequency impulse withstand voltage (50Hz) | KV | 50 |

| 25 | Temperature classification | B, F, and H | |

| 26 | Inner diameter | mm | >6 |

| 27 | External diameter | mm | <500 |

| 28 | Length | mm | 2000 |

| 29 | Mechanical strength | High (as per customers' needs) | |

| 30 | Surface smoothness/ roughness | Customizable | |

| 31 | Color | Light green (Other colors are customized.) | |

| NOTE: The above technical data is just for reference, and our fiberglass reinforced epoxy resin wound pipe is customizable according to clients' requirements. | |||

Product Testing Report

| Class F1 Test Report in French-01 | Class F1 Test Report in French-02 | Class F1 Test Report in French-03 | Class F1 Test Certificate in French-01 |

| Class F1 Test Report in English-01 | Class F1 Test Certificate in English-01 | Class I2 Test Report in French-02 | Class I2 Test Report in French-03 |

| Class I2 Test Certificate in French-01 | Class I2 Test Report in English-02 | Class I2 Test Report in English-03 | Class I2 Test Certificate in English-01 |

Related Names

Fiber Wrapping Tubing Supplier | Electrical Facility Tube | Spiral Tube Wholesale

Scan QR to Read

Links:https://www.globefindpro.com/products/62252.html

Links:https://www.globefindpro.com/products/62252.html

Recommended Products

-

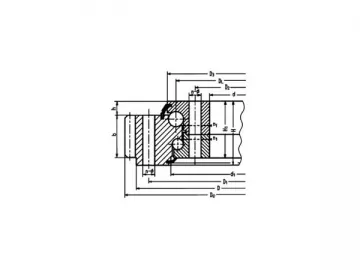

Four-Point Contact Ball Slewing Bearing(Without gear)

Four-Point Contact Ball Slewing Bearing(Without gear)

-

Fishpaper Tube

Fishpaper Tube

-

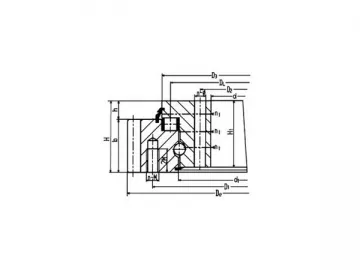

Ball-Roller Combination Slewing Bearing

Ball-Roller Combination Slewing Bearing

-

Four-Point Contact Ball Slewing Bearing

Four-Point Contact Ball Slewing Bearing

-

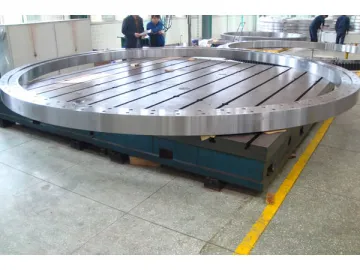

Fiberglass Reinforced Ring

Fiberglass Reinforced Ring

-

Double Row Ball Slewing Bearing(External gear)

Double Row Ball Slewing Bearing(External gear)

-

Four-Point Contact Ball Slewing Bearing(External gear)

Four-Point Contact Ball Slewing Bearing(External gear)

-

Cross-Roller Slewing Bearing

Cross-Roller Slewing Bearing

-

Phenolic Paper Laminated Tube

Phenolic Paper Laminated Tube

-

Magnetic Bar Sleeve

Magnetic Bar Sleeve

-

Epoxy Glass Cloth Laminated Tube / Pipe

Epoxy Glass Cloth Laminated Tube / Pipe

-

Self-lubricating Bushing

Self-lubricating Bushing