Features of Bar Joint

1. Application Range

The bar joint product can be found in such production systems as copiers, printers, digital cameras, projectors, communication products, PC goods, as well as electronic or electrical products, among others. Also, it can be used for the manufacturing of working position apparatus, the material storage and turnover equipment, the warehouse racking, the display rack for commercial purposes, and other feasible applications.

2. Remarkable Features

The modular type bar joints can be assembled at will. They are characterized by flexible structure, beautiful appearance, and no pollution. Additionally, they can improve the working environment, and meet the related requirements. Magic changes allow these joints to offer ultra strong material handling capacity. Precious resources show the great value of reutilization of the joint.

Based on body mechanics, the installation process can be finished only in use of an M6 hex wrench. These joints can cater for both transportation and storage of various precise and sensitive parts.

3. Manufacturing Technique

a. Molding Technique: This bar joint is manufactured by adoption of multi-way stamping process, featuring high durability, practical use, and no deformation forever.

b. Material: This joint makes use of the 2.5mm high-quality cold-rolled sheet, which is firstly cut into strips and then goes through multi-stage stamping process.

c. Surface Treatment: Its surface is subjected to polishing, stoving varnish, chrome plating, or electrophoresis process. Thanks to the electrophoresis technology, it can be nice, elegant, and rustproof forever.

4. How to Use

This bar joint and the flexible bar (lean pipe or steel-plastic composite pipe) can be combined to form all sorts of flexible workbench, warehouse racking, turnover vehicles, and some others. The bar joint possesses such characteristics as convenient disassembling, flexible assembling, the improvement of production efficiency, and some others. It is specially designed for assembly, production, maintenance, operation, and other work in factories.

The lean pipe joint is also an important component of the flexible bar type production system. It is derived from the superior-quality ABS plastic material. In comparison with metal joint, this bar joint can offer better toughness and more convenient installation. It is lightweight without the use of screw. Also, it can prevent the damage to the manufactured goods.

In use of the bar joint through special treatment, the surface of both moulds and workpieces is flat, smooth and rustproof. Additionally, the mould can be stripped easily.

In particular, the metal joint provides the original parts with small deformation during the plating process. After the surface layer is processed by chrome plating treatment, the hardness can be increased to over HR65. Moreover, the surface can offer strong resistance to corrosion, acids, abrasion, and high temperature of up to 500 degrees Celsius.

The flexible combined production logistics system is composed of the metal and plastic accessories, as well as the metal joint of steel-plastic composite pipe or lean pipe. It is lightweight, providing convenience for installation, adjustment, modification, disassembly, movement, as well as environmental protection.

Precautions

1. During transportation and storage processes, the rotary joints should avoid being hit or falling off, so that the interface and internal parts can avoid being damaged.

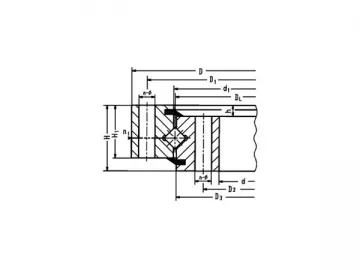

2. When the internal pipe is assembled, both dimension and weight should be paid attention to. The H8/e7 tolerance is ideal for the combination of the joint and the inner pipe of internal rotary union.

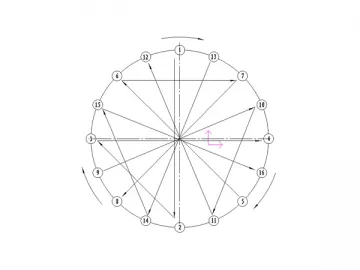

3. The support and rotation stopping of rotary joints ought to be proper. The general rod diameter should be 2mm smaller than the diameter of rotation stopper hole, so as not to affect the arbitrary adjustment and compensation of rotary joints.

4. For guaranteeing its fine operation, the rotary joint had better be concentric with the machine.

5. When the rotary joint with threaded connection is being mounted, the attention should be paid to whether the thread direction of both inner and outer pipes corresponds with the direction of rotation of a roller drum. Additionally, the thread rotation direction of inner and outer pipes should be also consistent.

6. A hose must be utilized to connect the rotary joint with pipeline. Our company recommends the use of satisfactory-flexibility metal hose. Rigid connection is prohibited.

7. The inlet and outlet of rotary union had better be directly connected with the hose. In this way, the joint bearing load can be reduced, and the service life can be prolonged.

Links:https://www.globefindpro.com/products/62290.html

-

Ready-mix Concrete Plant

Ready-mix Concrete Plant

-

Three-Row Roller Slewing Bearing(Without gear)

Three-Row Roller Slewing Bearing(Without gear)

-

Ship Unloader

Ship Unloader

-

Tunnel Boring Machine (TBM)

Tunnel Boring Machine (TBM)

-

Cross-Roller Slewing Bearing(External gear)

Cross-Roller Slewing Bearing(External gear)

-

Careful Craftsmanship

Careful Craftsmanship

-

Introduction to Characteristics and Properties of Lean Pipe

Introduction to Characteristics and Properties of Lean Pipe

-

Three-Row Roller Slewing Bearing(External gear)

Three-Row Roller Slewing Bearing(External gear)

-

Cross-Roller Slewing Bearing(Without gear)

Cross-Roller Slewing Bearing(Without gear)

-

Mobile Concrete Batching Plant

Mobile Concrete Batching Plant

-

Slewing Bearing Installation and Maintenance

Slewing Bearing Installation and Maintenance

-

Deck Crane

Deck Crane