STATCOM Structure

STATCOM Structure (Static Synchronous Compensator)

The static synchronous compensator, STATCOM/SVG, is composed of disconnectors, circuit breakers, series reactor, start-up circuit, link modules, control and protection system, as well as other components. For indoor applications, screen cabinet type installation is adopted. The whole system is structured by start-up cabinet, reactor, cascaded multilevel inverter cabinet, and control cabinet. When installed outdoors, an overall container structure is employed. The entire system is preassembled and preset in our factory, thus reducing the workload and time of on-site commissioning.

Static Synchronous Compensator Photo

Most of the components are imported. They have high performance and reliability. For example, film capacitor is used as DC support capacitor because of its high safety, reliability, and long life.

A. Start-up Cabinet

The left cabinet on the static synchronous compensator photo

B. Input Reactor

It is used to connect STATCOM with the grid, realizing power conversion.

It can reduce the ripples of the current output by the static synchronous compensator while reducing common-mode interference.

C. Cascaded Multilevel Inverter Cabinet

It is the core of the static synchronous compensator to realize power conversion.

Adopting modular design, all power units are identical in structure and electrical performance, so they are interchangeable.

The circuit of each chain knot (power unit) is shown below.

Power Unit

As the above figure shows, the circuit of each chain knot is composed of DC capacitor, H-bridge, control trigger circuit and other auxiliary circuits. The unit controller of power unit communicates with the main controller in the control cabinet through optical fiber, which improves the anti-interference ability of the entire system.

D. Control Cabinet

The control cabinet of our STATCOM adopts three-proofing design, damp-proof, mould-proof, and smoke-proof, which is of strong anti-interference. The optical fiber and accessories used in the signal transmission channel are imported and have high quality. Other accessories of the control system are from well-known suppliers at home and abroad.

The control system is mainly composed of main control unit, IPC, and UPS.

Main control unit: Realize core control; it consists of all kinds of functional boards.

IPC: Industrial personal computer, HMI and monitoring system

UPS: Supply power to the control screen.

Main Control Unit

Functions of Main Control Unit

Monitoring and Control

The control unit can realize pulse generation and distribution function according to the change in system voltage and reactive power. It can automatically regulate the device's reactive output and control the switching of the shunt reactor. It may also send control commands and analyze the real-time status of power units on the premise that the optical fibers are connected to the drive boards of power units.

Communications

The control unit can communicate with the host computer through the communication interface to realize local and remote communication. It can also be connected to the integrated automation systems in RS485 communication modes as per communication protocol standards such as Modbus.

Display

The controller adopts a LCD and the data can be saved for over 6 months. It can show the following information:

Basic information: STATCOM main wiring diagram, system time

Electrical parameters: system voltage, load current, loaded reactive power, SVG current, SVG reactive power, SVG access-point power factor, SVG grid-connection circuit breaker status, power unit status, protection actuation state, and fault alarm.

Protection

The complete equipment is integrated according to relevant integrated protection strategy. It has protection against power grid overvoltage, undervoltage, voltage imbalance, and overload, as well as power module overvoltage, undervoltage, overcurrent, and overtemperature. It is capable of automatically exiting in case of equipment failure. It can also protect the input interfaces and output interface.

HMI

It monitors and displays operating status and parameters of primary and secondary circuits. It can also adjust and set control parameters and protection fixed value. Users can carry out real-time monitoring through remote computer. The HMI has RJ45 expansion interface and communication conversion module. Remote communication monitoring interface is RS232 or RS485.

Links:https://www.globefindpro.com/products/62329.html

-

Stationary Asphalt Mixing Plant

Stationary Asphalt Mixing Plant

-

Men's and Women's Pants

Men's and Women's Pants

-

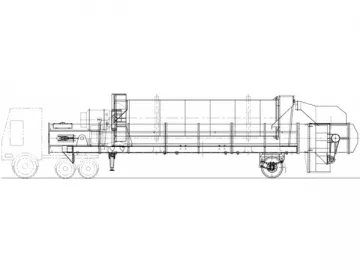

QLBY Series Mobile Asphalt Mixing Plant

QLBY Series Mobile Asphalt Mixing Plant

-

Ladies Casual Shirts

Ladies Casual Shirts

-

YLB Series Mobile Asphalt Mixing Plant

YLB Series Mobile Asphalt Mixing Plant

-

STATCOM Principle

STATCOM Principle

-

Pants

Pants

-

Mobile Type Stabilized Soil Mixing Plant

Mobile Type Stabilized Soil Mixing Plant

-

T-shirts

T-shirts

-

Women Formal Shirts

Women Formal Shirts

-

HLB Series Mobile Drum Mix Asphalt Plant

HLB Series Mobile Drum Mix Asphalt Plant

-

Men Formal Shirts

Men Formal Shirts