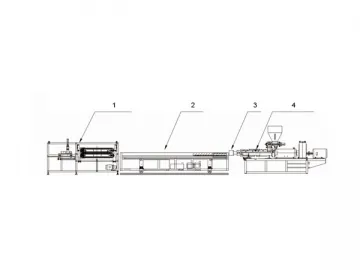

EPE Foam Cloth (for Package) Production Line

Product Features and Applications

The EPE foam cloth made in this production line is also known as pearl cotton. It is newly designed to replace the traditional package material, enjoying the advantages of good performance, low cost, high grade, and good looking appearance.

The EPE foam cloth is widely used to package various products, such as home appliances, precise instruments, bicycles, furniture, leather shoes, glass, high-grade porcelain, etc. According to customer’s requirement, the foamed cloth can be laminated by other material, and also can be thickened up to 100mm by the thickening instrument.

Equipment Features

The EPE foam cloth (for package) production line takes advantages of the latest foaming technology to ensure high foaming ratio of the finished product. This energy-efficient equipment selects superior components from both home and abroad to ensure stable and reliable quality. For example, it uses motor with good explosion-proof performance, SIEMENS frequency inverter for stable speed regulation, and Japan OMRON intelligent digital display temperature controller for accurate control. The whole machine comes with safe and reliable running, convenient operation, and other advantages.

Technical Parameters

| Extruder model | SM-EPE 90 | SM-EPE105 | SM-EPE120 | SM-EPE150 | SM-EPE170 |

| Product width (mm) | 1000-1400 | 1000-1500 | 1000-2000 | 1000-2000 | 1000-2000 |

| Product thickness (mm) | 0.5~4.5 | 0.5~6.5 | 0.8~8.0 | 1.0~12.0 | 2.0~16.0 |

| Capacity (kg/h) | 80-110 | 100-150 | 180-250 | 350-400 | 420-500 |

| Screw Dia & L/D Ratio | ¢90 55:1 | ¢105 55:1 | ¢120 55:1 | ¢150 55:1 | ¢170 55:1 |

| Foaming agent | Butane | ||||

| Foamed ratio | 20-40 | ||||

As an experienced EPE foam cloth (for package) production line manufacturer and supplier in China, we also offers PVC wavy board & trapezoidal board production line, PP-R, PP, PE single-layer multilayer water supply pipe production line, plastic shredder, and more.

Related Names

Pearl Cotton Extruder | Packaging Material Making Equipment

Links:https://www.globefindpro.com/products/62345.html

-

Plastic Crushers

Plastic Crushers

-

PVC, PP, PE, PC, ABS Small Profile Extrusion Line

PVC, PP, PE, PC, ABS Small Profile Extrusion Line

-

Parallel Twin-Screw Extruder Granulating Production Line

Parallel Twin-Screw Extruder Granulating Production Line

-

Post Processing Equipment for WPC Products

Post Processing Equipment for WPC Products

-

PP/PC Hollow Grid Sheet Production Line

PP/PC Hollow Grid Sheet Production Line

-

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

-

Pipe Belling Machine

Pipe Belling Machine

-

PP, PE Wide Waterproof Geotextile (Geomembrane) Production Line

PP, PE Wide Waterproof Geotextile (Geomembrane) Production Line

-

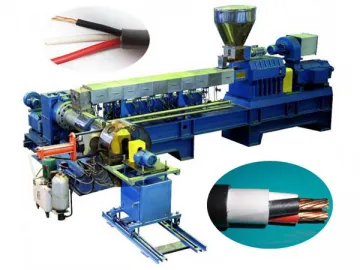

PVC Cable and Wire Production Line

PVC Cable and Wire Production Line

-

PVC Profile and PVC/PP/PE Wood Plastic Composite Profile Production Line

PVC Profile and PVC/PP/PE Wood Plastic Composite Profile Production Line

-

PVC Window Sill Profile Extrusion Line

PVC Window Sill Profile Extrusion Line

-

Moulds for Plastic Pipe and Sheet

Moulds for Plastic Pipe and Sheet