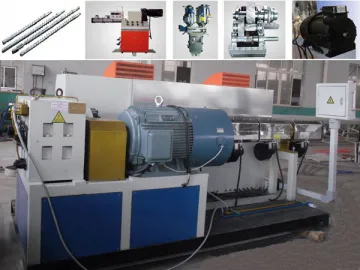

Parallel Twin-Screw Extruder Granulating Production Line

The parallel twin-screw extruder granulating production line makes full use of the high efficiency venting type single screw extruder or co-rotating or counter-rotating parallel twin screw extruder to achieve good plasticization and large output. The modular structure of the barrel and screw can also be changed in accordance with different plastics. This equipment is applicable to the modification and masterbatch palletizing of PE, PP, PA, ABS, PPS, PC, PET, PMMA, and other materials.

This granulating production line is composed of high-speed mixer, loader, extruder, pelletizing die head, cooling water trough or chain air cooling system, air-knife drying system, granule cutter, vibration screen, air blower loading system, and other parts. In addition, the water ring molded face cutting pelletizing or underwater hot-cutting palletizing is also available.

Flow Chart

1. Hopper

2. Extruder

3. Screen changer

4. Die head

6. Granule cutting motor

7. Air blower

8. Cooling cylinder

9. Air blower

10. Conveying

11. Material collection chamber

As a professional parallel twin-screw extruder granulating production line manufacturer and supplier in China, Xinquan Company also offers XPS foamed board production line, HDPE large diameter hollow wall winding pipe (underground drainage pipe) production line, wood powder pulverizer, and more.

Related Names

Masterbatch Granulator | Masterbatch Extruder

Links:https://www.globefindpro.com/products/62348.html

-

Post Processing Equipment for WPC Products

Post Processing Equipment for WPC Products

-

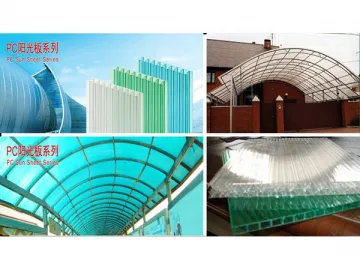

PP/PC Hollow Grid Sheet Production Line

PP/PC Hollow Grid Sheet Production Line

-

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

-

Gear Pump / Melt Metering Pump

Gear Pump / Melt Metering Pump

-

Small Caliber Flexible Hose Making Machine

Small Caliber Flexible Hose Making Machine

-

SJ Series New Type High Efficiency Single Screw Extruder

SJ Series New Type High Efficiency Single Screw Extruder

-

PVC, PP, PE, PC, ABS Small Profile Extrusion Line

PVC, PP, PE, PC, ABS Small Profile Extrusion Line

-

Plastic Crushers

Plastic Crushers

-

EPE Foam Cloth (for Package) Production Line

EPE Foam Cloth (for Package) Production Line

-

Pipe Belling Machine

Pipe Belling Machine

-

PP, PE Wide Waterproof Geotextile (Geomembrane) Production Line

PP, PE Wide Waterproof Geotextile (Geomembrane) Production Line

-

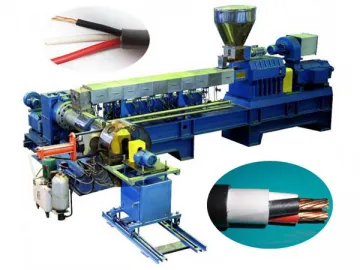

PVC Cable and Wire Production Line

PVC Cable and Wire Production Line