Plastic Vacuum Forming Machine

The XQ series vacuum forming machine is mainly applicable to PVC, PS, PSP, PP, PET, PP, and other materials. Through vacuum forming process, it can be used to make all kinds of close or open containers with thin wall, such as disposable lunch box, fast food plate, instant noodle bowl, western food box, inner lining of food packing, ice cream cup, candy box, cake box. It is also suitable for the production of packaging products of travel goods, children's toys, Chinese and Western medicines, electrical components, household hardware goods, as well as the breeding plate for farm crops and vegetables.

Characteristics

1. The plastic vacuum forming machine uses a combination of the pneumatic, mechanical and electric system to realize a series of automatic and continuous operations, including feeding, forming, mould releasing, transverse cutting, stacking, and so on. The PLC control system allows the machine to work more reliably.

2. It adopts double chain photoelectric control feeding mechanism, which ensures smooth and reliable sheet feeding. It can achieve stepless and accurate adjustment of the feeding width and length. It is suitable for the arrangement of different moulds. It also features a high material utilization.

3. The two-step vacuum function allows the machine to be suitable for large depth products forming and male, female mould forming. In addition, the mould can be replaced easily and quickly.

4. The heating system is configured with up and down heater, using the hollow far-infrared heating film. The unique partition temperature control system makes easy and fast heating adjustment possible, and ensures uniform heating, and energy conservation.

5. Due to the wind cooling and water fog system, the equipment can work continuously without water cooling. This makes it suitable for non-metal mould production.

6. The plastic vacuum forming machine comes with double-shaft loosening unit, transverse cutting unit, and pilling unit, which greatly improves production efficiency.

Technical Parameters

| Suitable Sheet | Pure PP, PS, PVC, PET |

| Sheet Thickness | 0.1-1.5 mm |

| Feeding Width | 500-680 mm |

| Feeding Length | 950-1220 mm (Stepless Adjustment) |

| Max. Forming Area | 680mm×1200mm |

| Max. Forming Depth | 150mm (Female Mould), 200mm (Male Mould) |

| Capacity | 3-8 Die/min |

| Power Supply | AC 380/220V, 48Kw (Max) |

| Air Consumption | 1.5M3/min (External air supply) |

| Working Pressure | 0.6Mpa |

| Dimension | 7500mm×2000mm×2250mm |

| Weight | 3000KG |

Our company is a specialized plastic vacuum forming machine manufacturer and supplier in China. We offer a vast range of products, including PVC multifunctional large caliber pipe production line, fan cooling type water chiller, PET sheet production line, and more.

Related Names

Thermoforming Machine | Vacuum Former

Links:https://www.globefindpro.com/products/62355.html

-

PET Sheet Production Line

PET Sheet Production Line

-

PVC and PVC Wood Plastic Composite Crust Foamed Board Production Line

PVC and PVC Wood Plastic Composite Crust Foamed Board Production Line

-

Fan Cooling Type Water Chiller

Fan Cooling Type Water Chiller

-

SJSZ Series Conical Twin Screw Extruder

SJSZ Series Conical Twin Screw Extruder

-

Film Laminating Machine for Board and Profile

Film Laminating Machine for Board and Profile

-

Plastic Shredders

Plastic Shredders

-

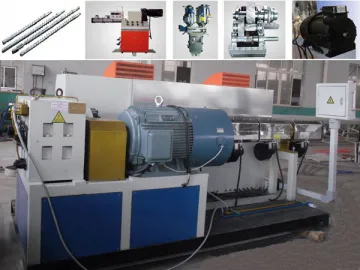

SJ Series New Type High Efficiency Single Screw Extruder

SJ Series New Type High Efficiency Single Screw Extruder

-

Small Caliber Flexible Hose Making Machine

Small Caliber Flexible Hose Making Machine

-

Gear Pump / Melt Metering Pump

Gear Pump / Melt Metering Pump

-

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

-

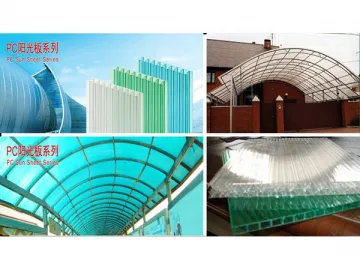

PP/PC Hollow Grid Sheet Production Line

PP/PC Hollow Grid Sheet Production Line

-

Post Processing Equipment for WPC Products

Post Processing Equipment for WPC Products