PET Sheet Production Line

PET Sheet Production Line

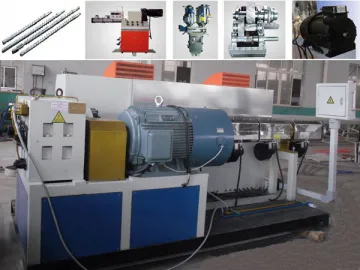

1. Extruder

2. Mould

3. Three-roll calender

4. Trimming unit

5. Cooling bracket

6. Haul-off machine

7. Double working station winder

Features and Applications of PET Sheet Product

The PET (APET, PETG, and CPET) sheet made in this production line is characterized by good processability, transparency, and insulation. It also has no toxicity, no innocuity, no environmental pollution, easy recycling, and other features. Especially in the field of food packaging, it is ideal for replacing the PVC product.

Features of Equipment

The APET, PETG, CPET single layer and multi-layer co-extrusion sheet production line utilizes advanced technology and mature workmanship, so that it can stably output high quality products. In comparison with the domestic similar equipment, the comprehensive capacity has been improved by 30%. It can also be used to produce PS, PP, PE, and other sheet products. The PET crystallization and drying system is developed absorbing internationally advanced technology, which ensures low dew point, low energy consumption, and other advantages. This further optimizes the performance of the complete extrusion line.

Main Technical Parameters

| Model | Single-layer PET sheet production line | Single-layer PET sheet production line | Multi-layer PET sheet production line |

| Model of extruder | SJ-120/33 | XQ-75/36 | SJ-120/33 SJ-65/33 |

| Width of product | 500-1200mm | 500-1200mm | 500-1200mm |

| Thickness of product | 0.2-1.2mm | 0.2-1.2mm | 0.2-1.2mm |

| Motor power | 132kw | 75kw | 132kw/45kw |

| Max. extrusion capacity | 350kg/h | 250 kg/h | 400 kg/h |

| Production line speed | 5-20m/min | 5-15m/min | 5-25m/min |

Note: The specifications are subject to change without prior notice.

As a specialized PET sheet production line manufacturer and supplier in China, Xinquan Company also provides PP/PC hollow grid sheet production line, PVC, PP, PE, PC, ABS small profile extrusion line, PVC cable and wire production line, etc.

Related Names

PET Plate Extrusion Line | PET Board Extrusion Machine

Links:https://www.globefindpro.com/products/62356.html

-

PVC and PVC Wood Plastic Composite Crust Foamed Board Production Line

PVC and PVC Wood Plastic Composite Crust Foamed Board Production Line

-

Fan Cooling Type Water Chiller

Fan Cooling Type Water Chiller

-

SJSZ Series Conical Twin Screw Extruder

SJSZ Series Conical Twin Screw Extruder

-

Film Laminating Machine for Board and Profile

Film Laminating Machine for Board and Profile

-

Plastic Shredders

Plastic Shredders

-

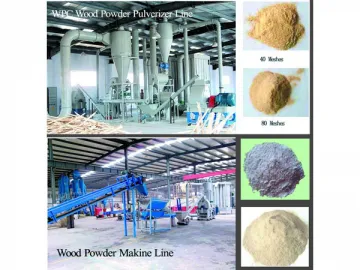

Wood Powder Pulverizer

Wood Powder Pulverizer

-

Plastic Vacuum Forming Machine

Plastic Vacuum Forming Machine

-

SJ Series New Type High Efficiency Single Screw Extruder

SJ Series New Type High Efficiency Single Screw Extruder

-

Small Caliber Flexible Hose Making Machine

Small Caliber Flexible Hose Making Machine

-

Gear Pump / Melt Metering Pump

Gear Pump / Melt Metering Pump

-

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

-

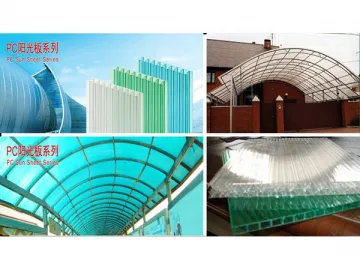

PP/PC Hollow Grid Sheet Production Line

PP/PC Hollow Grid Sheet Production Line