PVC and PVC Wood Plastic Composite Crust Foamed Board Production Line

The PVC and PVC wood composite crust foamed board production line is our new equipment developed according to the market need, and aiming to cost saving, material recycling and pollution reducing.

Product Characteristics

The WPC board, using PVC, waste wood or agricultural plants, CaCo3 and other additives as main material, can replace the steel plate and bamboo plate. The finished product is environmentally friendly, anti-corrosive, damp-proof, moth-proof, distortion-free, and can be processed under the same conditions as wood products. It also comes with low cost, light weight, and more than 30 recycle times, so that it has a broad application prospect in the future. The waste woods and plastics can be recycled to produce WPC boards. This not only helps to protect the environment, but also turns wasted into wealth.

The PVC and WPC crust foamed board produced in this extrusion line is widely used as building template, tool board, furniture and cabinet board, packaging plate, recycling box, advertisement plate, show plate, business plate, roof plate, ship profile, etc. This product has good resistance to weather, germ, corrosion, moisture, ant, fire, worm, mice, ultraviolet ray, etc. In addition, it has good thermal insulation, and can be used for a long time.

1. Conveyor

2. Crosscut machine

3. Eight-roller haul-off

4. Cooling bracket

5. Calibrating stand

6. Mould

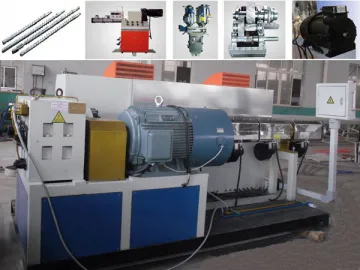

7. 80-type twin-screw extruder

Machine Features

This PVC and PVC wood composite crust foamed board production line adopts specially designed SJZ80 conical twin screw extruder with the advantages of easy and reliable operation., DC governor with large speed regulating scope, as well as imported well-known temperature controller with accurate temperature control.

The auxiliary units of the plastic crust foamed board production line include vacuum foaming stand, haul-off machine, cutting machine, stacker, etc.

1. The caterpillar type haul-off machine is designed with reasonable structure, using precise gear motor and frequency inverter to ensure powerful and stable hauling.

2. The cutting machine is characterized by high working reliability, high cutting accuracy, etc.

3. The stacker is matched with movable trolley and special rubber protection shield, ensuring easy and convenient operation, no damage to the product, and other characteristics.

4. In order to ensure good foaming result, a large forced cooling device is also available.

5. The whole auxiliary unit adopts a programmable logic controller (PLC) to ensure stable and reliable control.

Main Technical Parameters

| Model | Unit | SJSZ80/156 | SJSZ92/188 | SJSZ80/156, SJ65/132 | SJP92/32 |

| Product width | mm | 1220 | 1600 | 1600-2050 | 2050 |

| Product width | mm | 3-20 | 5-30 | 3-20 | 3-20 |

| Max. extrusion capacity | Kg/h | 350 | 500 | 600 | 450 |

| Power of extruder | KW | 75 | 110 | 120 | 75 |

Note: The specifications are subject to change without prior notice.

We are a professional PVC and PVC wood plastic composite crust foamed board production line manufacturer in China. We also provide HDPE large size water/gas supply pipe production line, fan cooling type water chiller, venting type single screw plastic extruder, and more.

Related Names

Plastic Crust Foamed Board Making Machine | Crust Foamed Board Extrusion Line

Links:https://www.globefindpro.com/products/62357.html

-

Fan Cooling Type Water Chiller

Fan Cooling Type Water Chiller

-

SJSZ Series Conical Twin Screw Extruder

SJSZ Series Conical Twin Screw Extruder

-

Film Laminating Machine for Board and Profile

Film Laminating Machine for Board and Profile

-

Plastic Shredders

Plastic Shredders

-

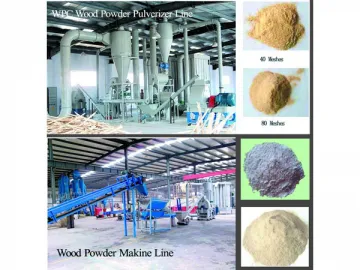

Wood Powder Pulverizer

Wood Powder Pulverizer

-

PVC and PVC Wood Plastic Composite Free Foamed Decorative Board Production Line

PVC and PVC Wood Plastic Composite Free Foamed Decorative Board Production Line

-

PET Sheet Production Line

PET Sheet Production Line

-

Plastic Vacuum Forming Machine

Plastic Vacuum Forming Machine

-

SJ Series New Type High Efficiency Single Screw Extruder

SJ Series New Type High Efficiency Single Screw Extruder

-

Small Caliber Flexible Hose Making Machine

Small Caliber Flexible Hose Making Machine

-

Gear Pump / Melt Metering Pump

Gear Pump / Melt Metering Pump

-

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line

Waste Plastic PP, PE, PET Film Crushing and Washing Production Line