PVC Wavy Board & Trapezoidal Board Production Line

The PVC wavy board and trapezoidal board production line is constructed with conical twin screw extruder, corresponding forming machine, haul-off unit and cutting unit. It can continuously produce UPVC wavy board with different colors, weather resistance and inflaming retarding used in buildings. As for the extruder, SJSZ65/132 type is recommended for the production of relatively smaller size board, while SJSZ80/156 is a good choice to produce large board.

This equipment is characterized by stable plasticization, compact structure, high automation, easy operation, etc. Hence, it is popular among manufacturers both at home and abroad.

Main Technical Parameter

| Extruder Model | SJSZ-65/132 | ||

| Die | T-type flat mould L=1000mm | Size of cooling mould1000mm 540mm | Haul-off power2.2kw (frequency inverter) |

| Forming machine | Cooling mode: by water | Cutting mode: Shear type ( pneumatic control) | |

| Big wave | R=15 H=16.5Pitch of waves 63mm | Haul-off speed: 0.5-5m/min | Cutting follow-up space: 500mm |

| Small wave | R=9 H=8 Pitch of waves 36mm | Haul-off roller: 1000mm | Pneumatic pressure: 0.4-0.6MPa |

PVC Wavy Board/Tile

This board production line can make PVC wavy board, which is also known as PVC corrugated tile, or roofing tile. It has powerful heat and sound insulation, as well as good resistance to leakage, wind, impact, fire, and corrosion. This environmentally friendly material also comes with high utilization ratio and quick installation.

Specification

Width: 930mm, 1130mm

Thickness: 0.8-4mm

Length: according to the customers’ need

Color: green, blue, gray, red, yellow, brown

Type: corrugated type, trapezoidal type

Application

The PVC corrugated tile made in this board production line is a high-end roof material mainly used in high-class factory building, steel structure factory building, warehouse, open fair, market passageway, and care shed. It can also be found in balcony, shelter, and other places with certain heat insulation requirements.

Installation

1. When cutting PVC wavy board, a fine-toothed saw should be used.

2. Either hand drill or power drill can be used for drilling. During drilling, the bottom should be supported to prevent swaying, and the bore diameter should be bigger than screw diameter by 50%.

3. When fixing screws, special rubber mat should be placed under the tile, and the screws should be properly fastened and should not be too tight.

4. The frame structure uses structural steel or wood as purlines, which should be neat and without deforming, as well as parallel and evenly spaced.

Xinquan Company is an experienced PVC wavy board & trapezoidal board production line manufacturer in China. We provide various types of products such as PP-R, PP, PE single-layer multilayer water supply pipe production line, high speed mixer, and PP strapping band equipment.

Related Names

Corrugated Tile Making Machine | Wave Tile Extrusion Line

Links:https://www.globefindpro.com/products/62367.html

-

PET Packing Strap Production Line

PET Packing Strap Production Line

-

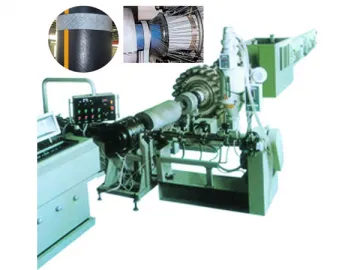

PVC Steel Wire Reinforced Flexible Pipe Production Line

PVC Steel Wire Reinforced Flexible Pipe Production Line

-

316 Stainless Steel Castings

316 Stainless Steel Castings

-

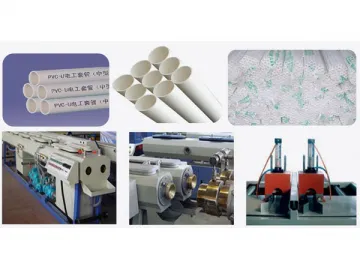

PVC Multifunctional Large Caliber Pipe Production Line

PVC Multifunctional Large Caliber Pipe Production Line

-

PVC Twin Pipe Extrusion Line

PVC Twin Pipe Extrusion Line

-

PE Carbon Spiral Reinforced Pipe Production Line

PE Carbon Spiral Reinforced Pipe Production Line

-

PVC Decorative and PVC Transparent Pharmaceutical Sheet Production Line

PVC Decorative and PVC Transparent Pharmaceutical Sheet Production Line

-

PE, PP, PS, ABS, PMMA, PET Sheet and Board Extrusion Line

PE, PP, PS, ABS, PMMA, PET Sheet and Board Extrusion Line

-

SJP Series Parallel Twin Screw Plastic Extrusion Machine

SJP Series Parallel Twin Screw Plastic Extrusion Machine

-

PVC and PVC Wood Plastic Composite Free Foamed Decorative Board Production Line

PVC and PVC Wood Plastic Composite Free Foamed Decorative Board Production Line

-

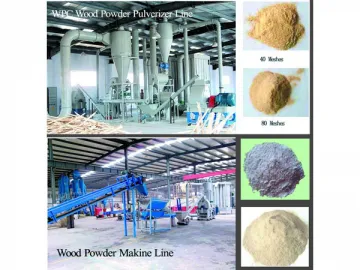

Wood Powder Pulverizer

Wood Powder Pulverizer

-

Plastic Shredders

Plastic Shredders