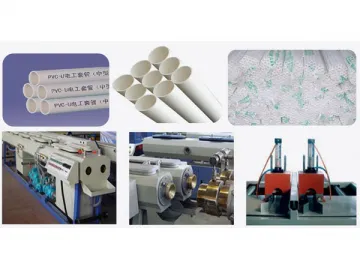

PVC Window and Door Profile Production Line

The PVC window and door profile production line uses PVC or UPVC as the raw material to produce various kinds of profiles for windows and doors. The complete unit is characterized by low energy consumption, stable performance, high efficiency, and so on. The profiles made from this line have various advantages such as beautiful appearance, strong compression resistance, good optical and thermal stability, aging resistance, etc.

1. The extruder and haul-off unit adopts the frequency inverter for speed control, and the whole line can realize stepless speed regulation.

2. The vacuum forming stand uses water circulation type closed and energy-saving vacuum system. Equipped with centralized water supply and quick-change coupler, it can realize fast and easy change of different calibration moulds. It can also select different length such as 4m, 6m or 8m.

3. The haul-off machine adopts belt type, which guarantees stable extrusion and no deformation of the profile.

4. The automatic film laminating machine of the PVC window and door profile production line ensures smooth surface of the extruded product.

5. The cutting machine uses the synchronous tracking system, which guarantees the smooth cutting section and no split after cutting.

Technical Specifications

| Extruder Model | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 |

| Max. Width of Product | 180 mm | 240 mm | 300 mm |

| Production Capacity | 80-100 kg/h | 180-240 kg/h | 300-350 kg/h |

| Speed | 0.6-6 m/min | 3-3.5 m/min | 4-5 m/min |

Xinquan Company is an experienced PVC window and door profile production line manufacturer in China. We provide a wide range of products, including PP strapping band equipment, PP-R, PP, PE single-layer multilayer water supply pipe production line, pipe belling machine, and more.

Related Names

Plastic Window Profile Making Machine | Equipment to Produce Profile of Window and Door

Links:https://www.globefindpro.com/products/62377.html

-

PVC, PE, PP Single Wall Corrugated Pipe Production Line

PVC, PE, PP Single Wall Corrugated Pipe Production Line

-

High Speed Mixers

High Speed Mixers

-

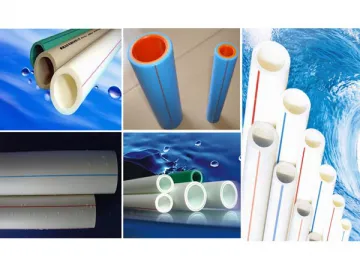

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line

-

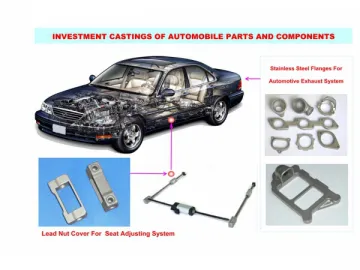

Auto Parts & Automobile Components

Auto Parts & Automobile Components

-

HDPE Silicon-cored Pipe Production Line

HDPE Silicon-cored Pipe Production Line

-

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

-

Stainless Steel Door Lever Handle

Stainless Steel Door Lever Handle

-

PP-R, PE-RT, PEX Cool/Hot Water Supply Pipe Production Line

PP-R, PE-RT, PEX Cool/Hot Water Supply Pipe Production Line

-

Industrial Building

Industrial Building

-

PE Carbon Spiral Reinforced Pipe Production Line

PE Carbon Spiral Reinforced Pipe Production Line

-

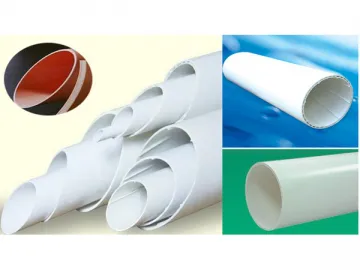

PVC Twin Pipe Extrusion Line

PVC Twin Pipe Extrusion Line

-

PVC Multifunctional Large Caliber Pipe Production Line

PVC Multifunctional Large Caliber Pipe Production Line