HDPE Silicon-cored Pipe Production Line

The HDPE silicon-cored pipe production line is developed utilizing Western Europe advanced technology and domestic leading automatic manufacturing line. It is equipped with the special mixing screw, which ensures extrusion with high speed and high performance. A waterfall and disk type calibrating sleeve is installed, and the production speed of the whole line can reach 16m/min.

The mould is specially designed to effectively reduce the thickness of the silicon layer and saves the cost. When changing the mould, this multi-purpose equipment can also be used to product nano antibacterial pipes and ordinary PP-R, PE, PEX pipes.

Features and Use of Pipe

This production line can make HDPE silicon-cored pipe widely used in the optical cable communication network system. The solid silicon layer of the inner pipe wall acts as a permanent lubricant. It is extruded together with the HDPE material and evenly distributed on the whole inner wall. Not likely to be peeled off nor broken away, it can be used as long as the silicon tube.

Main Technical Parameters

| Pipe specification | 32/26 34/28 40/33 50/40 | |

| Production speed | 3-10 | |

| Production capacity | 60-160 | |

| Installed power | 120 | |

| Compressed air | 0.4-0.6MP 0.1m3/h | |

| Cooling water consumption | 10 |

Xinquan Company is an experienced HDPE silicon-cored pipe production line manufacturer in China. We also provide PVC, PE, PP single wall corrugated pipe production line, PVC and PVC wood plastic composite crust foamed board production line, plastic crushers, and more.

Related Names

HDPE Silicon Core Tube Extruder | Plastic Pipe Extrusion Line

Links:https://www.globefindpro.com/products/62382.html

-

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

-

SJ Series Venting Type Single Screw Plastic Extruder

SJ Series Venting Type Single Screw Plastic Extruder

-

Casting Valve Body

Casting Valve Body

-

HDPE Large Diameter Hollow Wall Winding Pipe (Underground Drainage Pipe) Production Line

HDPE Large Diameter Hollow Wall Winding Pipe (Underground Drainage Pipe) Production Line

-

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

-

HDPE One-step Method PU Heat Preservation Pipe Production Line

HDPE One-step Method PU Heat Preservation Pipe Production Line

-

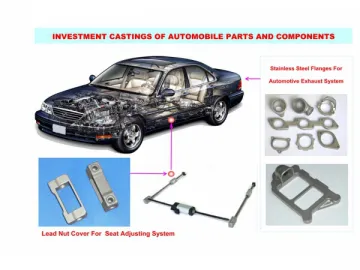

Auto Parts & Automobile Components

Auto Parts & Automobile Components

-

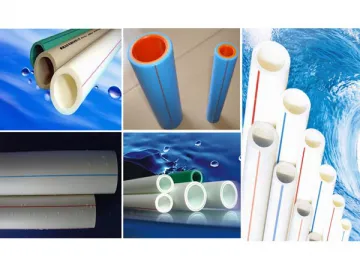

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line

-

High Speed Mixers

High Speed Mixers

-

PVC, PE, PP Single Wall Corrugated Pipe Production Line

PVC, PE, PP Single Wall Corrugated Pipe Production Line

-

PVC Window and Door Profile Production Line

PVC Window and Door Profile Production Line

-

Stainless Steel Door Lever Handle

Stainless Steel Door Lever Handle