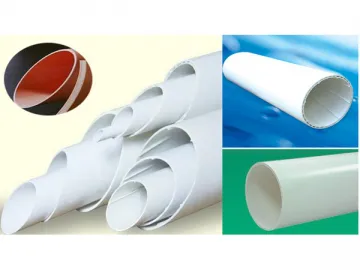

HDPE Large Diameter Hollow Wall Winding Pipe (Underground Drainage Pipe) Production Line

Production Line Features

The HDPE large diameter hollow wall winding pipe (underground drainage pipe) production line uses the double-stage pressure reduction type screw. The mixing and plasticizing process is promoted by using special elements. In coordination with high torque and high temperature control precision, the line can realize production by fully using recyclable materials.

The pipe production line can produce high quality product, due to combined feeding by two machines, spiral rotational forming and highly efficient compounding. It utilizes the special plastic and steel compounding technology, which ensures the compounding reliability, and highly enhances the pipe property. In addition, the frame of extruder can be adjusted, ensuring easy and flexible operation. The PLC automatic control system with reliable performance and convenient maintenance is also available.

Pipe Characteristics and Applications

The HDPE large diameter hollow wall winding pipe finished has the characteristics of high rigidity, light weight, and low cost. It also features good sealing performance, acid and alkali resistance, corrosion resistance, long service life, and convenient construction. The pipe has been widely used in the underground water drainage system.

Technical Parameters

| Model | Pipe Spec. (mm) | Max. output(kg/h) | Outline size (L X W X H) (m) |

| SG-800 | Φ200-800 | 280 | 8X20X2.6 |

| SG-1200 | Φ600-1200 | 500 | 10X23X2.7 |

| SG-1500 | Φ1000-1500 | 600 | 28X18X6 |

| SG-2000 | Φ1500-2000 | 700 | 30X20X7 |

| SG-3000 | Φ2000-3000 | 800 | 32X20X8 |

Xinquan Company is a specialized HDPE large diameter hollow wall winding pipe (underground drainage pipe) production line manufacturer in China. We also offer waste plastic PP, PE, PET film crushing and washing production line, parallel twin screw plastic extrusion machine, wood powder pulverizer, and more.

Related Names

Winding Pipe Extrusion Line | Plastic Pipe Extruder

Links:https://www.globefindpro.com/products/62386.html

-

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

-

HDPE One-step Method PU Heat Preservation Pipe Production Line

HDPE One-step Method PU Heat Preservation Pipe Production Line

-

PVC Fiber Reinforced Flexible Hose Production Line

PVC Fiber Reinforced Flexible Hose Production Line

-

HDPE Large Size Water/Gas Supply Pipe Production Line

HDPE Large Size Water/Gas Supply Pipe Production Line

-

PP Strapping Band Equipment

PP Strapping Band Equipment

-

Casting Sprocket Wheel & Ratchet Wheel

Casting Sprocket Wheel & Ratchet Wheel

-

Casting Valve Body

Casting Valve Body

-

SJ Series Venting Type Single Screw Plastic Extruder

SJ Series Venting Type Single Screw Plastic Extruder

-

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

-

HDPE Silicon-cored Pipe Production Line

HDPE Silicon-cored Pipe Production Line

-

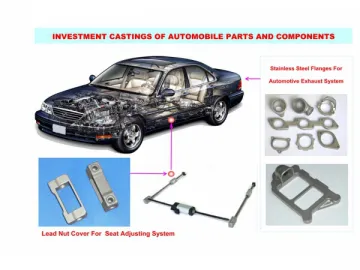

Auto Parts & Automobile Components

Auto Parts & Automobile Components

-

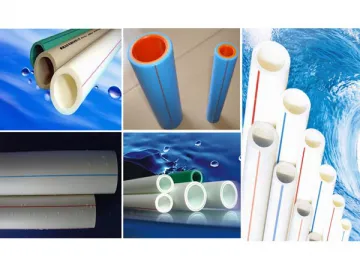

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line

PP-R, PP, PE Single-layer Multilayer Water Supply Pipe Production Line