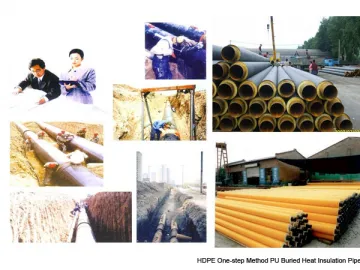

HDPE One-step Method PU Heat Preservation Pipe Production Line

Pipe Features and Use

The HDPE one-step method PU heat preservation pipe production line utilizes HDPE three-layer protective design, which allows the pipe to achieve a strong anti-corrosion layer and a highly extended service life. In the case of no accidents, the anti-corrosion capacity can sustain as long as 50 years. Due to its good performance, this pipe is widely used as petroleum and natural gas supply pipe, civil gas and water supply pipe, chemical pipeline, underground cable protective pipe, buried moisture-proof pipeline.

Machine Introduction

The HDPE one-step method PU heat preservation pipe production line is able to simultaneously apply the heat-insulation layer and corrosion-resistance layer to the steel pipe, which ensures continuous production with high efficiency and low cost.

In addition, it uses in-line impeller blasting, and in-line spraying anti-rust treatment. The in-line fully automatic hydraulic deviation rectifying unit provides high accuracy, as well as stable and reliable operation.

The pipe conveying unit uses multiple plastic core-rubber-tires clamping drive, so that the steel pipes can be stably transmitted. In general, this machine can be used to produce pipes with a diameter of ф48-ф1000mm.

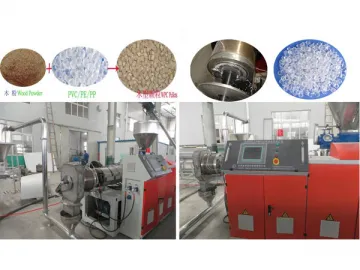

As a specialized HDPE one-step method PU heat preservation pipe production line manufacturer and supplier in China, we also provide PE carbon spiral reinforced pipe production line, plastic vacuum forming machine, PVC profile and PVC/PP/PE wood plastic composite profile production line, etc.

Related Names

Thermal Insulated Pipe Making Machine | Heat Insulation Pipe Extrusion Line

Links:https://www.globefindpro.com/products/62388.html

-

PVC Fiber Reinforced Flexible Hose Production Line

PVC Fiber Reinforced Flexible Hose Production Line

-

HDPE Large Size Water/Gas Supply Pipe Production Line

HDPE Large Size Water/Gas Supply Pipe Production Line

-

PP Strapping Band Equipment

PP Strapping Band Equipment

-

Casting Sprocket Wheel & Ratchet Wheel

Casting Sprocket Wheel & Ratchet Wheel

-

S45C Medium Carbon Steel Casting

S45C Medium Carbon Steel Casting

-

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

-

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

PVC Wide Plastic Flooring Sheet and Waterproof Membrane Roll Production Line

-

HDPE Large Diameter Hollow Wall Winding Pipe (Underground Drainage Pipe) Production Line

HDPE Large Diameter Hollow Wall Winding Pipe (Underground Drainage Pipe) Production Line

-

Casting Valve Body

Casting Valve Body

-

SJ Series Venting Type Single Screw Plastic Extruder

SJ Series Venting Type Single Screw Plastic Extruder

-

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

U-PVC Foamed Inside Spiral Silent Pipe Making Machine

-

HDPE Silicon-cored Pipe Production Line

HDPE Silicon-cored Pipe Production Line