Peroxide Crosslinked Polyethylene (PE-Xa) Pipe Production Line

1. Advanced structure: The main machine of the peroxide crosslink (PE-Xa) pipe production line adopts the new spherical crank mechanism with high working efficiency.

2. Stable performance: The optimized and integrated design ensures long-term stable operation of the machine.

3. Low noise: The noise is lower than 45 DB when two positions are working at the same time.

4. High output: The output of the peroxide crosslink (PE-Xa) pipe production line is larger than 100t per line.

5. Stable thickness of pipe wall: The unique adjustment mechanism allows for simple regulation of the pipe wall thickness with small fluctuations.

6. Online thermal printer: It can print clear letters that can not be easily erased.

7. Complete and reliable auxiliary machines: The haul-off machine offers automatic adjustment of hauling tension, while the winding machine provides automatic stacking of the pipes.

8. State-of-the-art technology: The pipes can be directly formed under a high temperature of 260°C, with no flowing processes for cross linking.

Technical Parameters

| Main machine | Main motor | 7.5kw |

| Feeder | 2x60w | |

| Hot oil pump | 0.75kw | |

| Heater | 9kw | |

| Haul-off | Haul-off motor | 2x90w |

| Winder | Reduction motor | 150w |

| Mixer | 200L | 7.5kw |

| 100L | 5.5kw | |

| Dryer | 345L | 9kw |

| 150L | 6kw |

As a China-based peroxide crosslinked polyethylene (PE-Xa) pipe production line manufacturer, we also offer PVC multifunctional large caliber pipe production line, PVC wide plastic flooring sheet and waterproof membrane roll production line, fan cooling type water chiller and more.

Related Names

PE-Xa Pipe Extruder | Plastic Pipe Extrusion Equipment

Links:https://www.globefindpro.com/products/62397.html

-

Carbon Steel Casting Nut Cover

Carbon Steel Casting Nut Cover

-

HDPE/PVC Double Wall Corrugated Pipe Extrusion Line

HDPE/PVC Double Wall Corrugated Pipe Extrusion Line

-

Precision Casting Gears & Tooth Profiled Parts

Precision Casting Gears & Tooth Profiled Parts

-

420 Stainless Steel Castings

420 Stainless Steel Castings

-

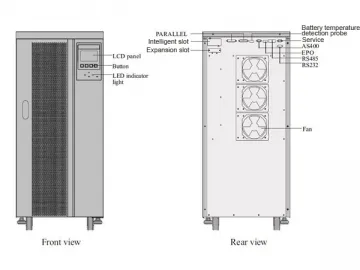

20-80KVA Online UPS with LCD Display

20-80KVA Online UPS with LCD Display

-

Chamfering Machine

Chamfering Machine

-

Plastic PP, PE Strand Cutting and Double Stage Pelletizing Production Line

Plastic PP, PE Strand Cutting and Double Stage Pelletizing Production Line

-

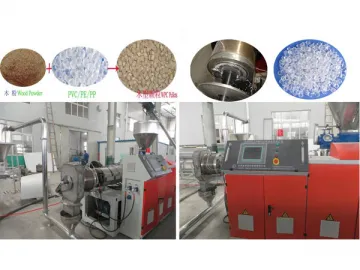

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

-

S45C Medium Carbon Steel Casting

S45C Medium Carbon Steel Casting

-

Casting Sprocket Wheel & Ratchet Wheel

Casting Sprocket Wheel & Ratchet Wheel

-

PP Strapping Band Equipment

PP Strapping Band Equipment

-

HDPE Large Size Water/Gas Supply Pipe Production Line

HDPE Large Size Water/Gas Supply Pipe Production Line