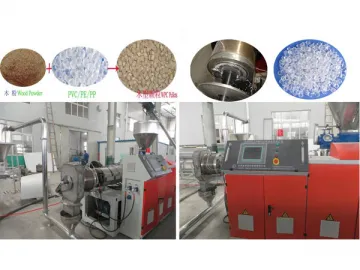

HDPE/PVC Double Wall Corrugated Pipe Extrusion Line

Features and Use of Pipe

The HDPE/PVC double wall corrugated pipe with an inner diameter of Φ110mm-Φ800mm comes with a smooth inner wall, a trapezoidal and corrugated outer wall, as well as a hollow layer between inner and outer wall. This unique design of wall structure makes the pipe enjoy large ring stiffness, light weight, high pressure resistance, good toughness, corrosion resistance, abrasion resistance, convenient construction, low installation costs, long service life, and other features.

This type of pipe made in the extrusion line is widely used in the field of municipal renovation project, construction, industrial and agricultural drainage, agricultural water-saving irrigation, sewage treatment works, and so on. It is the best alternative to traditional cement pipe, cast iron pipe and pipes made of other materials.

Features of Equipment

The XQ series HDPE/PVC double wall corrugated pipe extrusion line is suitable for the high speed extrusion of PE, PP and PVC material. It adopts direct extrusion molding process, as well as human-machine interface (HMI) control system. This helps to ensure high degree of automation, reliable and stable production, and stable running. Hence, the equipment enjoys good reputation among customers both at home and abroad.

Single Screw Extruder

The high speed and high efficiency single screw extruder is adopted for extruding relevant plastic materials. It is equipped with barrel of grooved design, air blower of low noise, and hard gear reducer of high speed. Two extruders are used to independently feed the materials for the inner and outer layer of the corrugated pipe. Hence, it can realize pipe production with the inner and outer layer using different materials, while maintaining high extruding efficiency.

Extrusion Die

Due to the two channel structure, and nitriding and polishing treatment, different materials and ring stiffness of pipes can be produced. The special die structure assures forming stability, and uniform wall thickness of the inner and outer wall.

Pipe Corrugators

The pipe forming machine adopts horizontal structure with shuttle type transmission, which reduces the amount of mold blocks, investment cost and energy consumption. Due to the advanced water cooling system and vacuum forming system, the production speed is greatly increased. The special on-line belling function decreases cost and improves efficiency. The corrugated forming system and water-air forced cooling system allow for production at high speed.

Mold blocks

The corrugated forming mold blocks made using special aluminum alloy and going through precision casting enjoy high accuracy and strength, as well as superior heat dissipation effect. They adopt SIEMENS servo motor and advanced self-lubrication system. This helps ensure running accuracy and quality stability. The mould blocks are less likely to abrasion because of the programmable lubricating system. Hence, the service life is greatly lengthened.

Control system

The professional SIEMENS PLC control system ensures high automation, reliable running, and easy operation of the HDPE/PVC double wall corrugated pipe extrusion line. With the remote communication function, it can realize remote fault diagnosis and removal.

As an experienced HDPE/PVC double wall corrugated pipe extrusion line manufacturer in China, Xinquan Company also offers PVC profile and PVC/PP/PE wood plastic composite profile production line, parallel twin-screw extruder granulating production line, PP/PC hollow grid sheet production line, and more.

Related Names

Plastic Pipe Production Line | Double Wall Corrugated Tube Extruder

Links:https://www.globefindpro.com/products/62399.html

-

Precision Casting Gears & Tooth Profiled Parts

Precision Casting Gears & Tooth Profiled Parts

-

420 Stainless Steel Castings

420 Stainless Steel Castings

-

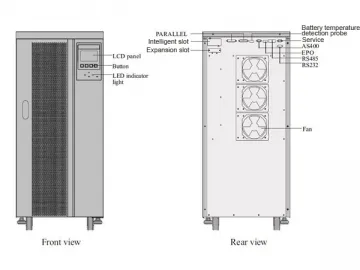

20-80KVA Online UPS with LCD Display

20-80KVA Online UPS with LCD Display

-

Chamfering Machine

Chamfering Machine

-

UPS Battery Pack

UPS Battery Pack

-

MPPT Solar Charge Controller

MPPT Solar Charge Controller

-

Carbon Steel Casting Nut Cover

Carbon Steel Casting Nut Cover

-

Peroxide Crosslinked Polyethylene (PE-Xa) Pipe Production Line

Peroxide Crosslinked Polyethylene (PE-Xa) Pipe Production Line

-

Plastic PP, PE Strand Cutting and Double Stage Pelletizing Production Line

Plastic PP, PE Strand Cutting and Double Stage Pelletizing Production Line

-

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

PVC / WPC Hot Cutting Pelletizing / Granulating Machine

-

S45C Medium Carbon Steel Casting

S45C Medium Carbon Steel Casting

-

Casting Sprocket Wheel & Ratchet Wheel

Casting Sprocket Wheel & Ratchet Wheel