Concrete Batching Machine

Concrete Batching Machine

Structure

Our PL800, PL1200, PL1600, PL2400, PL3200 and PL4800 concrete batching machine consists of storage hopper, mechanical rack, unloading cylinder door or unloading belt conveyor, sensor, measuring hopper, discharge belt conveyor, etc.

Characteristics

1. Our PL series concrete batching machine could automatically batch the raw materials for concrete such as sand, stone, cement, etc. according to the requirements of the concrete mix.

2. The measurement method adopts electronic measurement (load cell hanging measurement). It features centralized control by electric control cabinet, digital display, wired remote control, etc. You can set up our device and ingredients in a host of layouts. Thus our product can be used in different working conditions.

3. The machine offers varied weighing methods. For instance, it supports gauging the weight of all materials using the belt weigher, and also supports independent weighing of different types of aggregates. It has advantages such as high measuring precision, fast material batching, strong control performance, and high reliability.

4. The discharge mode for our batching machine can be selected from belt discharge mode and pneumatic discharge mode. (1) The belt discharge mode adopts cumulative measuring by the measuring hopper, and it is widely used with small size mixer to offer accurate weighing and automatic drop level correction. (2) The pneumatic discharge mode could use cumulative measurement and single measurement. With a vibrator in the sand container to avoid potential sand bagging inside the hopper, this method also adopts large batching machine hopper with dual discharge door to achieve rough and fine measurement. The measuring accuracy is improved as well. The pneumatic control devices are integrated in the control box to facilitate operation and maintenance. The service time of our pneumatic control devices can be guaranteed as well.

Model Selection

You can select our product according to your mixer models or the weighing range. Our PL800, PL1200, PL1600, PL2400, PL3200 and PL4800 models can be used to offer a measuring capacity of 800L, 1200L, 1600L, 2400L, 3200L, 4800L, respectively.

Applications

The concrete batching machine is used to complete material batching automatically. To illustrate, it can complete sand, stone, and concrete materials’ batching procedures automatically, according to the desired concrete mixing ratios. It is an important component in a concrete batching plant.

Technical Specification

Model | Measuring Hopper Capacity | Storage Hopper Capacity | Power Consumption | Accuracy | Measuring Method | Gross Weight |

PL800 | 800L | 2 ×3000L | 7.4KW | ±2% | Electronic Measurement | 2380kg |

PL800- Ⅲ | 800L | 3 ×2500L | 5.5KW | ±2% | Electronic Measurement | 33000kg |

PL1200 | 1200L | 2 ×3000L | 7.4KW | ±2% | Electronic Measurement | 4380kg |

PL1200- Ⅲ | 1200L | 3 ×3000L | 5.5KW | ±2% | Electronic Measurement | 4040kg |

PL1600- Ⅲ A | 1600L | 2 ×4000L | 8.5KW | ±2% | Electronic Measurement | 4500kg |

PL1600- Ⅲ B | 1600L | 3 ×6000L | 8.5KW | ±2% | Electronic Measurement | 5460kg |

PL1600- Ⅲ C | 1600L | 3 ×8000L | 8.5KW | ±2% | Electronic Measurement | 6870kg |

PL1600- Ⅲ D | 1600L | 3 ×12000L | 14KW | ±2% | Electronic Measurement | 9160kg |

PL1600- Ⅲ E | 1600L | 3 ×18000L | 8.5KW | ±2% | Electronic Measurement | 10500kg |

PL2400- Ⅲ B | 2400L | 3 ×6000L | 10.5KW | ±2% | Electronic Measurement | 5830kg |

PL2400- Ⅲ C | 2400L | 3 ×8000L | 10.5KW | ±2% | Electronic Measurement | 6240kg |

PL2400- Ⅲ D | 2400L | 3 ×12000L | 14KW | ±2% | Electronic Measurement | 10500kg |

PL2400- Ⅲ E | 2400L | 3 ×15000L | 10.5KW | ±2% | Electronic Measurement | 11000kg |

PL3200- Ⅳ A | 3200L | 4 ×20000L | 16.5KW | ±2% | Electronic Measurement | 15000kg |

PL4800- Ⅳ A | 4800L | 4 ×25000L | 16.5KW | ±2% | Electronic Measurement | 18000kg |

Related Names

Batching Machinery | Automatic Batching Equipment | Batching Machine with Different Capacities

Links:https://www.globefindpro.com/products/62757.html

-

WL920 Wheel Loader

WL920 Wheel Loader

-

Optional Loader Parts

Optional Loader Parts

-

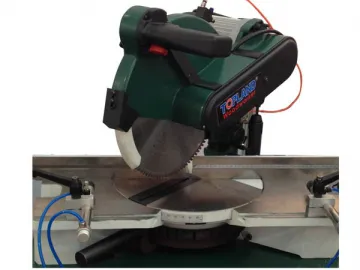

Manual Aluminum Profile Cutting Machine with Circular Saw

Manual Aluminum Profile Cutting Machine with Circular Saw

-

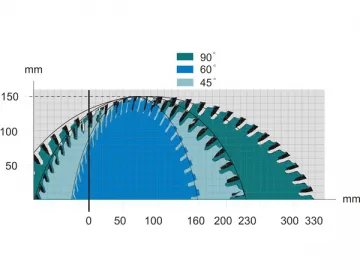

Heavy Duty Miter Sawing Machine

Heavy Duty Miter Sawing Machine

-

ACR260M Aluminum Profile Copy Routing Machine

ACR260M Aluminum Profile Copy Routing Machine

-

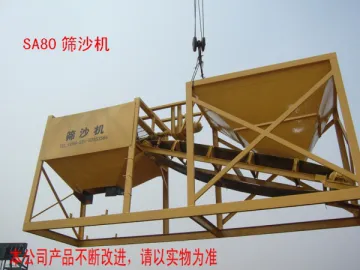

Sand Screening Machine

Sand Screening Machine

-

Concrete Distributor

Concrete Distributor

-

WL910 Wheel Loader

WL910 Wheel Loader

-

WL916 Wheel Loader

WL916 Wheel Loader

-

Semi-Automatic Aluminium Profile Up-Cutting Circular Sawing Machine

Semi-Automatic Aluminium Profile Up-Cutting Circular Sawing Machine

-

Conference Room Table

Conference Room Table

-

Three Seat Office Sofa

Three Seat Office Sofa