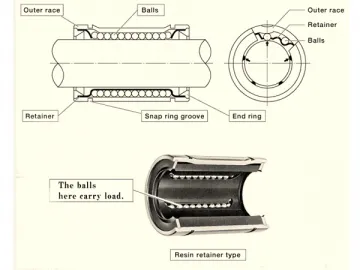

Linear Bearing

Linear Bearing

The linear bearing is used in conjunction with the cylindrical shaft for unlimited linear motion. Due to the point contact with quenched drive shaft, the ball allows small load. In addition, the steel balls rotate with minimal friction resistance, so as to obtain high-precision smooth movement. Therefore, this low-cost product is mainly used in light industry machinery that moves in straight line, such as CNC machine tool, laser welding machine, tile cutter, mitre saw, paper bowl machine, engraving machine, screen printing machine, etc.

Structure and Characteristics

MYT linear motion bearing is composed of outer ring, balls, retainer and end ring. The retainer constrains balls in a circular orbit, while the end ring allows the retainer to be fixed in the outer ring.

Seal type: e.g LM20UU

No U: No seal

U: Single seal

UU: Double seals

1. After heat treatment, the outer ring enjoys sufficient hardness, so as to ensure long traveling life and satisfactory bearing capacity.

2. The common type linear bearing can be easily installed in any direction. It can work accurately when used together with the shaft. The mounting surface is also easy to process.

3. Each set has interchangeability due to the standardized size and high machining accuracy. This brings great convenience for replacement of worn or damaged ones.

4. With complete models for option, the product can meet the different needs of different customers.

Installation

As Fig.1 shows, the user should push by hand or gently beat the linear bearing instead of beating the retaining ring or seal ring at two ends when installing the product into the housing. Then the shaft should be carefully inserted without striking against steel balls. If two parallel shafts are used at the same time, special attention should be paid to the shaft parallelism, so as to ensure the smooth operation of the product.

Installation Cases

The common installation of linear bearing requires appropriate resistance when pushing it into housing bores. However, we recommend trying to adopt a loose fit, or the accuracy of the product will decline. Fig.2-Fig.6 introduces several installation structures and fixing methods for reference.

Links:https://www.globefindpro.com/products/62816.html

-

SM-E Corrugated Paperboard Double Facer

SM-E Corrugated Paperboard Double Facer

-

Hotel Chain in Mexico

Hotel Chain in Mexico

-

Shopping Center in Singapore

Shopping Center in Singapore

-

Corrugated Paper Hydraulic Shaftless Mill Roll Stand

Corrugated Paper Hydraulic Shaftless Mill Roll Stand

-

Automatic Carton Folding and Gluing Machine

Automatic Carton Folding and Gluing Machine

-

GM-C Double Layer Corrugated Paperboard Gluing Machine

GM-C Double Layer Corrugated Paperboard Gluing Machine

-

4870Kg Fuel Tank Truck

4870Kg Fuel Tank Truck

-

Other Pictures

Other Pictures

-

Engineering Dump Truck

Engineering Dump Truck

-

D-Series High Speed Paperboard Printing Slotting and Die Cutting Machine

D-Series High Speed Paperboard Printing Slotting and Die Cutting Machine

-

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

-

Road Wrecker

Road Wrecker