Variable Speed Drive Air Compressor

Variable Speed Drive Air Compressor

JUFENG variable speed drive air compressor is equipped with inverter to adjust the speed, especially when the air demand is fluctuating significantly and when the compressor operates at no more than 70% of full capacity, thus saving the energy and ensuring long service time. The intergraded inverters are furnished with load reactors on 380 volt and load or line reactor on 420 volt system, preventing the variable speed drive from noisiness tripping due to the unbalanced power supply. In order to eliminate any current draw spikes, the motor will operate at its lowest ramp up time.

Our variable speed screw air compressor will maintain optimum pressure within one PSI, which allows setting the operating pressure 20% lower compared to load or off load systems. Moreover, the screw air compressor unit is equipped with a controller which is manufactured in line with ISO 9001 quality management system standard. With the controller, it can communicate with two other air compressors with a similar controller via adding the optional program. For applications requiring more efficient operation to save energy, Jufeng provides an extensive line of variable speed drive screw compressors from 7hp to 350hp.

Cost Comparison

Normal Screw Air Compressor

VSD Screw Air Compressor

Energy cost

Maintenance cost

Machine cost

Energy saving

Cost Comparison

The Guangzhou Jufeng VSD screw air compressor which can change the motor RPM accurately in accordance with the air consumption under steady discharge pressure, only delivers the required air and only consumes the energy of necessary compressed air. Therefore, it is energy saving during the whole set machine operation. The cost of saving energy is much higher than the cost of machine itseStart and Operation

Full Current (%)

△start

Direct- start

Soft- start

VSD start

Start and Operation

The figure shows a comparison of several types of start up. We can see that the VSD air compressor is slowly accelerating started which is more stable than the soft-start compressor, thus completely avoiding the current peak. Variable speed screw air compressor is the preferred choice for the areas lacking of electricity.

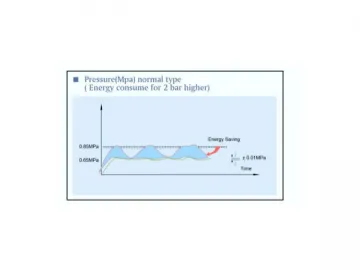

Pressure (Mpa) normal type

(Energy consume for 2 bar higher)

0.85MPa 0.65MPa

Energy Saving

±0.01MPa

Time

Electricity Consumption Comparison

The figure shows the energy consumption comparison between the general air compressor and VSD air compressor.

The VSD screw air compressor not only changes the rotating speed based on air consumption, but also balances both air supply and air usage, thus saving more than 35% energy compared to a normal compressor. With the stable pressure supply, it can effectively prevent pressure loss, which also contributes to energy saving.

Constant pressure air supply, balance of production

Normal type

Air Usage Electricity Consume

Air Usage Normal type Energy Consume

VSD type

Air Usage Electricity Consume

Air Usage VSD type Energy Con

Electricity saving result

ON-OFF button

Capacity adjust

VSD adjust

Electricity Saving Result

Two fields can display the result of energy saving, the loss of no-loading and loss of fluctuating pressure, according to the research between the VSD screw air compressor and a normal screw air compressor. For instance, for a 55KW screw air compressor, 70% air delivery in a year, the VSD type can save about 80000KWH energy. The cost of VSD can be taken back within two years.

Links:https://www.globefindpro.com/products/62873.html

-

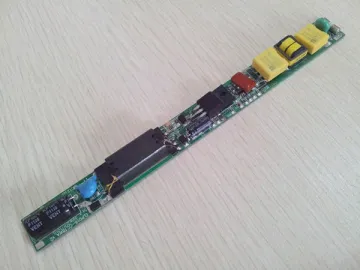

Isolated LED Driver

Isolated LED Driver

-

Reception Room and Sample Room

Reception Room and Sample Room

-

XY-44 Series Core Drilling Rig

XY-44 Series Core Drilling Rig

-

Business Team and Activities

Business Team and Activities

-

Dimmable T8 LED Tube

Dimmable T8 LED Tube

-

Square Stainless Steel Tube

Square Stainless Steel Tube

-

Illumination Improvement for a Jewelry Store in Dubai

Illumination Improvement for a Jewelry Store in Dubai

-

Belt Driven Rotary Screw Compressor (GHH Air End)

Belt Driven Rotary Screw Compressor (GHH Air End)

-

AirHorse Screw Compressor (GHH Air End)

AirHorse Screw Compressor (GHH Air End)

-

Direct Driven Rotary Screw Air Compressor

Direct Driven Rotary Screw Air Compressor

-

LED lights for a famous Clothing Shop in Germany

LED lights for a famous Clothing Shop in Germany

-

XY-3 Series Drilling Rig

XY-3 Series Drilling Rig