30V 235W/240W/245W/250W/255W Black Mono Solar Panel

30V 235W/240W/245W/250W/255W Black Mono Solar Panel

SL235-255TU-30MDBK

Electrical Data

Maximum Power (W) | 235 | 240 | 245 | 250 | 255 |

Optimum Power Voltage (Vmp) (V) | 31.56 | 31.95 | 32.12 | 32.28 | 32.46 |

Optimum Operating Current (Imp) (A) | 7.45 | 7.51 | 7.63 | 7.74 | 7.86 |

Open Circuit Voltage (Voc) (V) | 37.62 | 37.94 | 38.03 | 38.12 | 38.20 |

Short Circuit Current (Isc) (A) | 7.97 | 8.04 | 8.16 | 8.29 | 8.41 |

Photoelectric Conversion Efficiency of Cell (%) | 17.21 | 17.58 | 17.94 | 18.31 | 18.67 |

Photoelectric Conversion Efficiency of Whole Module (%) | 14.47 | 14.78 | 15.09 | 15.40 | 15.71 |

Wattage Tolerance | 0% to 3% | ||||

Nominal Operating Cell Temperature (°C) | 47±2 | ||||

Temperature Characteristics

Temperature Coefficient of Isc (%) | 0.04 |

Temperature Coefficient of Voc (%) | -0.35 |

Temperature Coefficient of Pm (%) | -0.45 |

Temperature Coefficient of Im (%) | 0.04 |

Temperature Coefficient of Vm (%) | -0.35 |

Components and Technical Data

Solar Cell (mm) | 156×156 Mono Type |

Number of Cell (pcs) | 6×10 |

Size of Module (mm) | 1640×990×40 |

Front Glass Thickness (mm) | 3.2 |

Maximum Load Capacity of Surface (Pa) (Pa)Capacity | 2400-5400 |

Allowable Hail Load | 23m/s,7.53g |

Weight Per Piece (kg) | 18.6 |

Junction Box Type | TUV Certification |

Bypass Diode Rating (A) | 12 |

Cable and Connector Type | TUV Certification |

Frame | 40mm Aluminum Alloy |

Back Sheet | TPT |

Temperature Range (°C) | -40 to 85 |

Fill Factor (%) | 70-76 |

Standard Test Conditions | AM1.5, 1000W, 25±2°C |

Packing

Packing | Wooden Box |

1×20 inches Container | 14Pallets/332pcs |

1×40 inches HQ | 28Pallets/840pcs |

Benefits

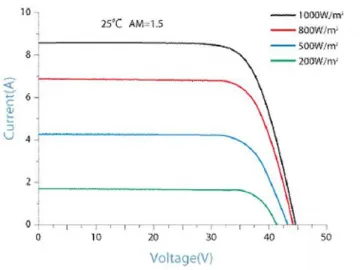

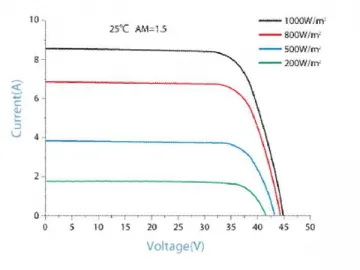

IV-Curves

Engineering Drawings

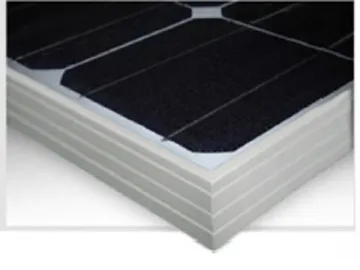

This series of black mono solar panels is designed with the power ranging from 235W to 255W. The photoelectric conversion efficiency of the solar cells is from 17.21% to 18.67%. Then, the conversion efficiency of the whole module can be 14.47% to 15.71%. Featuring high reliability and high conversion efficiency, the product has been widely used in the fields involving in solar energy.

When assembling the black mono solar panel, we link the needed solar cells, the number of which is dependent on the desired electrical configuration, according to the certain dot matrix. Then, the linked solar cells are put in the vacuum to conduct lamination process. After being heated and curing, the solar cells with the laminations are encapsulated and sealed with protective lightweight aluminum frame and advanced encapsulation technology. Thus, our product can be guaranteed to have the strong capabilities of resistance to wind, rain, high-intensity irradiation of ultraviolet and corrosion by rain and other corrosive matters.

Links:https://www.globefindpro.com/products/63137.html

-

Flexible High Gloss Printing Decorative Film

Flexible High Gloss Printing Decorative Film

-

36P 280W/285W/290W/295W/300W Polycrystalline Solar Panel

36P 280W/285W/290W/295W/300W Polycrystalline Solar Panel

-

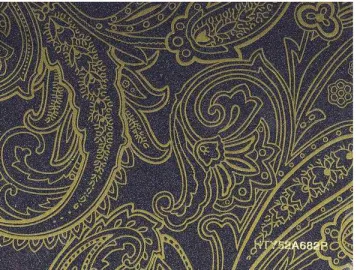

Golden Black High Gloss Printing PVC Film

Golden Black High Gloss Printing PVC Film

-

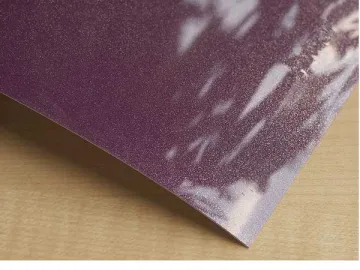

Deep Red High Gloss Metallic PVC Film

Deep Red High Gloss Metallic PVC Film

-

36V 290W/295W/300W/305W/310W TU Certified White Mono Solar Panel

36V 290W/295W/300W/305W/310W TU Certified White Mono Solar Panel

-

36V 175W/180W/185W White Mono Solar Panel

36V 175W/180W/185W White Mono Solar Panel

-

BF6X Cell Phone Battery for Motorola

BF6X Cell Phone Battery for Motorola

-

HW4X Cell Phone Battery for Motorola

HW4X Cell Phone Battery for Motorola

-

BH6X Cell Phone Battery for Motorola

BH6X Cell Phone Battery for Motorola

-

BTR6425B Mobile Phone Battery for HTC

BTR6425B Mobile Phone Battery for HTC

-

AB553850DC Mobile Phone Battery for Samsung

AB553850DC Mobile Phone Battery for Samsung

-

BF5X Cell Phone Battery for Motorola

BF5X Cell Phone Battery for Motorola