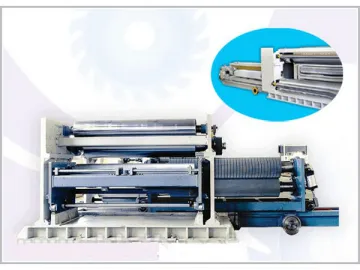

High Speed Carton Flexo Printer Slotter Die Cutter

10mm, either in left direction or right direction. The shaft is also designed with locking mechanism.

4. The paper feeding system comes with a pneumatic-type automatic raising and lowering device as well as idling device. During paperboard feeding, the anilox roller is lowered to contact with the printing plate. After the feeding, it will be raised and separated with the printing plat.

5. The printing unit adopts the pneumatic ink circulating system in printing as well as the strainer to catch impurities thus ensuring the printing quality.

6. The phase position of the printing unit can be adjusted in 360 degree by using the PLC touch screen and electrical numeric control system.

7. The automatic zero setting device ensures the devices have uniform adjustment standard. Users can easily correct the positions of the devices during proof printing of a couple of paperboards. This reduces the waste of paperboards.

Die cutting unit

1. The rubber roller can do crosswise movements along a spiral path. Its moving distance is close to 40mm.

2. The phase position of the die-cut roller can be adjusted in 360 degree by adopting the PLC and electrical numeric control system. Phase position adjustment can be done during operation or when the machine stops running.

3. The crosswise movement of the die-cut roller can also be adjusted by the PLC electrical numeric input-type control system. The adjustment range is ±10mm.

4. The gap between the rubber roller and die-cut roller is adjusted by the cylinder or the self-lock mechanism. Cylinder-type adjustment features large range and fast speed. Gap adjustment can reduce the damage of the rubber and extend the use life of the rubber.

5. Gap adjustment of the feeding rollers also adopts the self-locking mechanism.

6. The speed compensation device enables the rubber roller move with the printing plate roller so that the surface speed of the rubber roller can be controlled by the knife and the shape of the output is kept the same with that of the cutting knife.

7. The machine is equipped with the rubber roller correction device.

Stacking unit

1. The arm of the stacker can be manually or automatically operated. The stacker is equipped with a protection device to prevent the sudden drop the arm thus ensuring the safety of the operator.

2. The rising and descending movement of the stacking platform is powered by the high-strength chain.

3. The stacking height is 1600mm.

4. The tilting height of the stacker is adjusted according to the increasing height of the paperboard piles. The lifting motor is designed with braking system. This allows the stacking platform to maintain in a fixed position without dropping.

5. The pneumatic design enables the supporting plate to open automatically for holding cardboards when the stacking cardboards reach the pre-set stacking height.

6. The wrinkled belt can prevent the cardboards from sliding off the supporting plate.

4. The paper feeding system comes with a pneumatic-type automatic raising and lowering device as well as idling device. During paperboard feeding, the anilox roller is lowered to contact with the printing plate. After the feeding, it will be raised and separated with the printing plat.

5. The printing unit adopts the pneumatic ink circulating system in printing as well as the strainer to catch impurities thus ensuring the printing quality.

6. The phase position of the printing unit can be adjusted in 360 degree by using the PLC touch screen and electrical numeric control system.

7. The automatic zero setting device ensures the devices have uniform adjustment standard. Users can easily correct the positions of the devices during proof printing of a couple of paperboards. This reduces the waste of paperboards.

Die cutting unit

1. The rubber roller can do crosswise movements along a spiral path. Its moving distance is close to 40mm.

2. The phase position of the die-cut roller can be adjusted in 360 degree by adopting the PLC and electrical numeric control system. Phase position adjustment can be done during operation or when the machine stops running.

3. The crosswise movement of the die-cut roller can also be adjusted by the PLC electrical numeric input-type control system. The adjustment range is ±10mm.

4. The gap between the rubber roller and die-cut roller is adjusted by the cylinder or the self-lock mechanism. Cylinder-type adjustment features large range and fast speed. Gap adjustment can reduce the damage of the rubber and extend the use life of the rubber.

5. Gap adjustment of the feeding rollers also adopts the self-locking mechanism.

6. The speed compensation device enables the rubber roller move with the printing plate roller so that the surface speed of the rubber roller can be controlled by the knife and the shape of the output is kept the same with that of the cutting knife.

7. The machine is equipped with the rubber roller correction device.

Stacking unit

1. The arm of the stacker can be manually or automatically operated. The stacker is equipped with a protection device to prevent the sudden drop the arm thus ensuring the safety of the operator.

2. The rising and descending movement of the stacking platform is powered by the high-strength chain.

3. The stacking height is 1600mm.

4. The tilting height of the stacker is adjusted according to the increasing height of the paperboard piles. The lifting motor is designed with braking system. This allows the stacking platform to maintain in a fixed position without dropping.

5. The pneumatic design enables the supporting plate to open automatically for holding cardboards when the stacking cardboards reach the pre-set stacking height.

6. The wrinkled belt can prevent the cardboards from sliding off the supporting plate.

Related Names

Multifunction Equipment for Carton Box Making | Printing Unit | Stacking Unit and Die Cutting Unit | Carton Box Machinery

Scan QR to Read

Links:https://www.globefindpro.com/products/63825.html

Links:https://www.globefindpro.com/products/63825.html

Recommended Products

-

Paperboard Gluing Machine

Paperboard Gluing Machine

-

D-Glucosamine Hydrochloride/Sulfate Capsule and Tablet

D-Glucosamine Hydrochloride/Sulfate Capsule and Tablet

-

Chitosan Soap

Chitosan Soap

-

Rotary Cardboard Slotting Machine

Rotary Cardboard Slotting Machine

-

Rotary Cardboard Cut Off Machine

Rotary Cardboard Cut Off Machine

-

Automatic Flute Laminating Machine

Automatic Flute Laminating Machine

-

Automatic Box Gluer Machine

Automatic Box Gluer Machine

-

Helical Knives NC Cutting Machine

Helical Knives NC Cutting Machine

-

GS-Chitosanase

GS-Chitosanase

-

Carton Creasing and Cutting Machine

Carton Creasing and Cutting Machine

-

Corrugated Board Twin Facer

Corrugated Board Twin Facer

-

Chitosan Capsule / Tablet

Chitosan Capsule / Tablet