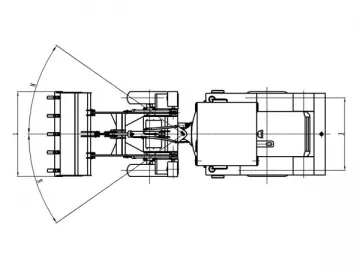

6 Ton Wheel Loader

6 Ton Wheel Loader

Construction Engineering Machine

With the distinguished technology, the 6 ton wheel loader adopts durable accessories, reliable braking system and stable structure. Moreover, it offers easy maintenance for users.

Main Technical Specifications

Item | Parameter | |

Rated Bucket Capacity | 3.5m³ | |

Rated Load | 6000kg | |

Operating Weight | 20000kg | |

Min. Ground Clearance | 467mm | |

Max. Breakout Force | 171kn | |

Max. Traction | 201kn | |

Boom Lifting Time | 5.7s | |

Total Time of Three Devices | 10.9s | |

Engine | Model | Cummins QSC8.3 |

Type | 6-Cylinder, 4-Stroke, Electronic Injection, Turbo Charging | |

Rated Power | 179kw | |

Rated Rotary Speed | 2200r/min | |

Travel Speed | Forward/Backward Gear I | 6/6km/h |

Forward/Backward Gear II | 11/11km/h | |

Forward/Backward Gear III | 22/22km/h | |

Forward Gear IV | 36km/h | |

Tire Model | 23.5-25 | |

Durable Accessories

1.The 6 ton wheel loader chooses the Shangchai turbocharged engine which performs with electric start and flameout, low fuel consumption, strong power and is energy saving.

2. ZF electro hydraulic control transmission offers smooth gear shifting and it exerts advanced but reliable performance. Aided with KD gear function, the machine reduces the frequency of gear shifting while working and improves the operation efficiency.

3. Our product is equipped with wet slip limited drive axle. With the brake installed inside, the drive axle can repel the water and dust so that there is no need to maintain it. Even if the machine is running in water or on loose and soft earth, the driving and braking will be not affected. Moreover, the center swing of the rear axle could reduce the impact of the additional torque and external load on the drive system

4. The product uses the full hydraulic wet brake that combines the urgent brake and the parking brake to ensure the safe driving and operating. Therein, the braking elements improve the reliability of the system.

Excellent Technology

1.With the technology of dual pump flow-converging, the wheel loader realizes the hydraulic flow expanding steering. Due to the single-handle pilot control, this product is flexible and convenient to be operated.

2. As to the steering limit, the hydraulic control is superior to the mechanical limit. Apart from the special working mechanism, our machine adopts double steering limit to reduce the unloading impact.

3. Due to the electromagnet positioning technology, the machine can lay the bucket flat automatically to reduce the working labor of the operator, improving the working efficiency. With the function of swing arm lifting limit, the machine could prevent the mechanical impact so as to reduce the fatigue of the operator.

4. With the long wheelbase and centered distributed articulated center, the wheel loader has good stability. The center articulated bearing in front and rear frame ensures that the stable frame could bear the repeated torsion on uneven ground. Equipped with the high strength frame, our product is suitable for using in heavy duty working conditions.

Reliable Structure and Comfortable Operation Environment

1.The 6 ton wheel loader focuses on the integrated structure strength. With the finite element analysis, we try to reduce the stress at the concentration position and ensure the product can adapt to various dangerous working conditions.

2. Its independent cab is configured with air conditioner, radio and adjustable seat. It has the advantages of vast view and vibration decreasing. Our machine offers a comfortable operating environment so as to improve the working efficiency.

3. Our machine is equipped with an inclinable steering column integrated with an instrument panel. Anyone could change the angle of the steering column only with one control lever to figure out the proper operating position. Due to the design of the panel, the operators can get the information on the monitor clearly and grasp the exact status of machine.

4. Due to new intelligent electronic monitoring system, the operator could monitor the machine accurately in real-time according to the displayed information on the control panel.

Convenient Maintenance

1.The wheel loader allows integrated oil filling so that the service person is easy to access to the maintenance point in higher efficiency than to climb to the high place.

2. As the side plates of the shield and rear shield are easy to be opened or closed so that it is convenient to inspect and maintain the engine and other parts routinely.

Links:https://www.globefindpro.com/products/63868.html

-

Chitosan (Medical /Food / Industrial Grade)

Chitosan (Medical /Food / Industrial Grade)

-

Metal Clip Connection Plasterboard Partition Clean Room Wall Panel System

Metal Clip Connection Plasterboard Partition Clean Room Wall Panel System

-

Double Layer Glass Window

Double Layer Glass Window

-

DC Grade D-Glucosamine HCl

DC Grade D-Glucosamine HCl

-

2-2.5 Ton Wheel Loader

2-2.5 Ton Wheel Loader

-

1.6-1.8 Ton Wheel Loader

1.6-1.8 Ton Wheel Loader

-

DC Grade D-Glucosamine Sulfate 2NaCl

DC Grade D-Glucosamine Sulfate 2NaCl

-

Special Molecular Weight Chitosan

Special Molecular Weight Chitosan

-

Steel Color Plate Clean Room Door

Steel Color Plate Clean Room Door

-

Chitosan Lactate

Chitosan Lactate

-

Chitosan Azelate (Cosmetic Specialized)

Chitosan Azelate (Cosmetic Specialized)

-

Melamine Skin Clean Room Door

Melamine Skin Clean Room Door