Precision Terminal

PrecisionTerminal

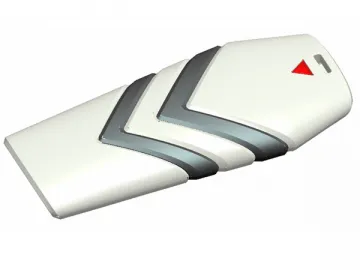

Our precision terminalutilizes the copper material of C5210 and C2680. For the C5210, it has theadvantages of good wear and corrosion resistance, as well as high intensity. Inaddition, it can be hot forged, cut and lubricated by itself. When the copperstrip C2680 in compliance with JIS standard is used, the molded precisionterminal has high heat and electric conductivity, as well as excellentductility and corrosion resistance.

Detailed Information of PrecisionTerminal

| Project Name | Precision terminal |

| Number of Parts | 1*2 |

| Material | C2680-R/C5210R-H |

| Product Size | 3.1*3.0*1.25mm |

| Country/Customer | China |

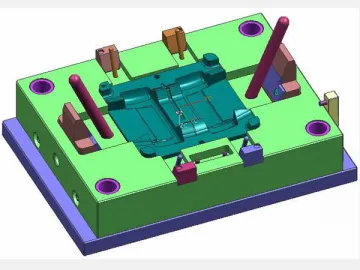

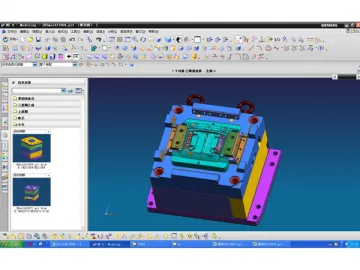

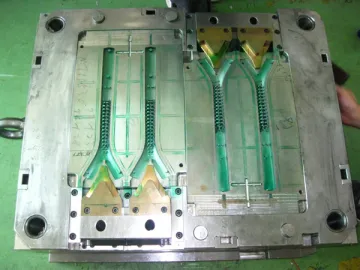

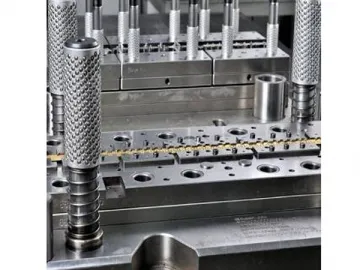

DetailedDescription of Precision Terminal Mold

| Cavity No. | 1*16 | Metal Material | C5210 | Tonnage of Moulding Machine | 50-75T |

| Core Cavity Material | SKD61/VIKING | Mold Life Warranty | 1KK | Mould Type | 3 plate |

| Mould Size | 286X350X400 | Mold Base | MISUMI | Mold Features | 2 slider No lifter |

| Mould Weight | 250 KD | Runner System | Could runner | Gate Type | NA |

Are you enquiring

Q 1.: What do you need to make aninitial quotation?

Q 2.: What else do you need to make afirm quotation to make order?

Q 3.: How much time do you need toquote?

The precisionterminal mold can be used to manufacture high precision terminal. The terminalis a component used to connect devices and the external conductor, playing arole of signal transmission and electric conduction. The size of the moldedterminal is 3.1mm × 3.0mm × 1.25mm. In addition, the mold weight is 250kg andmold size is 286mm × 350mm × 400mm. With up to 16 cavities, it is able tomanufacture 16 products at a time, and work at high efficiency. Selectingdurable SKD61 and VIKING steel as the cavity material, the mold can complete1kk terminal production.

Links:https://www.globefindpro.com/products/64385.html