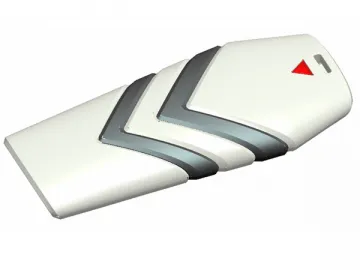

Insert Handle Mold

Insert Handle Mold

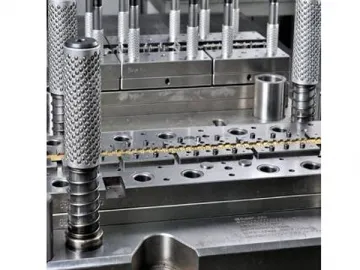

The insert handle moldutilizes the insert molding process, which is a highly efficient alternative tothe assembly of discrete parts using soldering, connectors, fasteners, oradhesives. First, a custom-built mold is loaded with inserts robotically ormanually, and then the molten plastic is injected into the mold. Upon cooling,the mold opens and the ejected components are separated from the sprues and inspected. Ingeneral, post-molding assembly includes a variety of operations, such as diecutting, bonding, microsoldering,and circuit testing.

Our insert handle mold is designed with increased flexibility. As the insertmolding joins numerous components with thermoplastic, it can greatly minimizeassembly and labor costs. In addition, it is able to provide components withreduced size and weight by combining the physical strength of resin and metalinserts. The utilized thermoplastic resin also ensures strong resistance toshock and vibration. What’s more, our insert molded component enjoys increasedreliability, as it can prevent part loosening, misalignment, improperterminations, and other problems.

Product Information

| Project Name | Insert handle |

| Number of Parts | 2 parts in 1 tooling |

| Material | PA6 0gf |

| Product Size | 161*58*41 |

| Exported Country/Customer | India |

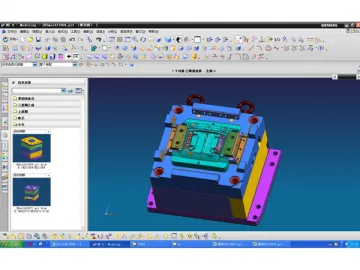

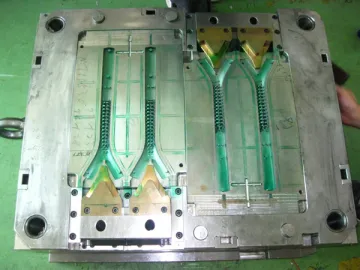

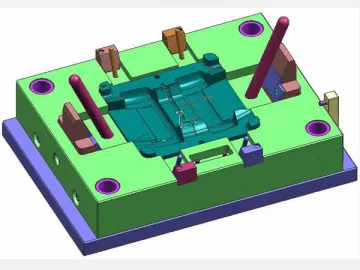

Mold Details

| Cavity No. | 1*1 | Plastic | PA6 0gf | Tonnage Of Moulding Machine | 100T |

| Core Cavity Material | 1.8407 German Steel | Mold Life Warranty | 500K | Mould Type | 3 plate |

| Mould Size | 400*450*300 | Mold Base | LKM S50C | Mold Features | 4 slider,2 lifters |

| Mould Weight | 400 kg | Runner System | YUDO Hot runner | Gate Type | Needle Valve gate, Open gate |

Links:https://www.globefindpro.com/products/64386.html