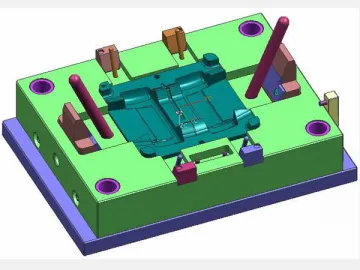

PMMA Injection Mold

PMMA Injection Mold

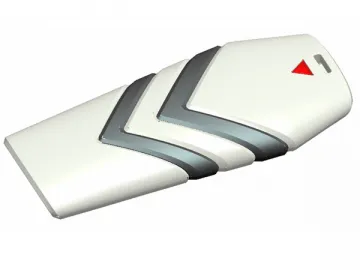

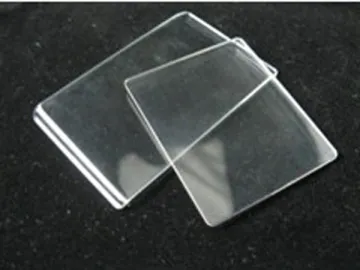

The PMMA injection moldis especially applicable to the production of LCD panel. The injected PMMAmaterial can be finally shaped into the LCD panel with required shape, as wellas high transparency, acid resistance and alkali resistance. This colorless andtransparent acrylic plastic is better than other plastics when used forproduction of this product.

Detailed LCD Panel Information

| Project Name | LCD panel |

| Number of Parts | 2 parts in 1 tooling |

| Material | PMMA |

| Product Size | 66.29*41.88*1.5mm |

| Exported Country/Customer | Austrial |

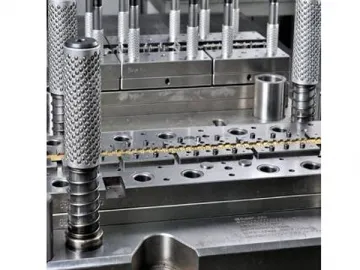

Detailed LCD Panel Mold Description

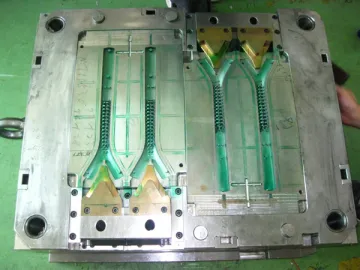

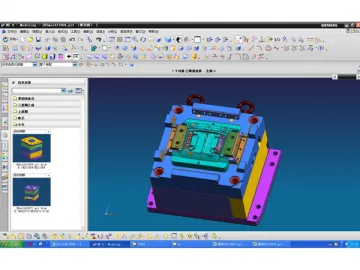

| Cavity No. | 1*2 | Plastic | PMMA | Tonnage of Moulding Machine | 120T |

| Core Cavity Material | ASSAB 136H 48-52HRC | Mold Life Warranty | 500K | Mould Type | 2 plate |

| Mould Size | 300*300*250 | Mold Base | P20 | Mold Features | NA |

| Mould Weight | 160 kg | Runner system | Cold runner | Gate Type | Direct gate |

Thereason why adopt PMMA in the injection molding of our LCD panel is that it canachieve a high light transmittance of over 92% when the thickness is 3 mm.Also, the resolution is less than 0.5% haze. In general, the material iswidely used for the production of instruments panels in automotive andpharmaceutical industry.

Our PMMA injectionmold is suited for the manufacture of LCD panels with the size of 66.29mm ×41.88mm × 1.5mm. The mold size is 300mm × 300mm × 250mm, while the mold weightreaches 160kg. In addition, the mold material is ASSAB136H and 48-52HRC steelfor the cavity and P20 steel for the base. Hence, it is strong enough and comeswith no decline in manufacturing quality even under stress impact orenvironmental corrosion. It can guarantee the production of 500K LCD panel. Itis also ideal for users who want to improve production efficiency, as it uses adual-cavity design to process two panels in the meantime.

Links:https://www.globefindpro.com/products/64390.html