Oil Drilling Filtering Screen

Oil Drilling Filtering Screen

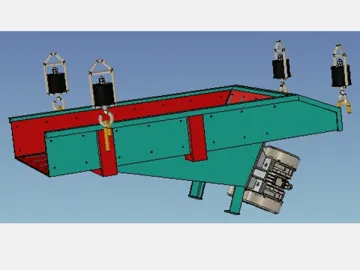

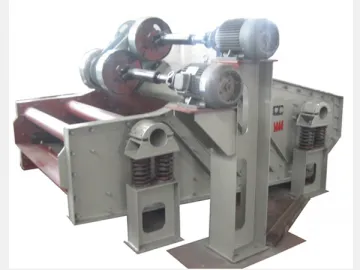

The oil drilling filtering screen is a three section type linearvibrating screen used for filtering out harmful solid particles in the drillingfluid. It is mainly used in combination with various over 2000 meters drillingrigs installed on oil fields.

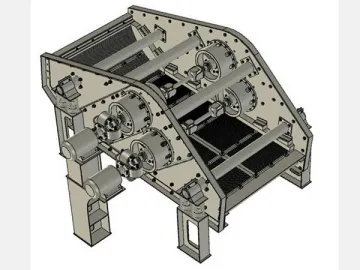

Features

1. The oil drilling filtering screen adopts two highfrequency vibration motors.

2. It offers compact structure, light weight and occupies a small floorarea.

3. The screen causes low noise, which is lower than 78 dBA.

4. Both flat plate screen and wave type screen are available. The use of wavetype screen contributes to enlarging screening area and increasing the liquidhandling capacity to 125%.

5. The single side tensioning system allows for fast screen changes. In fact,each screen can be replaced within one minute.

6. The screen frame adopts manual hydraulic cylinder push rod lift structure.Quick changing of screen frame tilt angle between -1° and 5° can be realizedwithout affecting the continuous operation of the equipment. This allowseffective handling of the slurry.

7. The composite spring has good vibration isolation effect, low noise and longservice life.

8. The vibrating screen feeder (mud box) and wellhead overflow pipelineinterface can connect the pipeline from the two sides or the back of thefeeder, according to users’ requirements.

9. The layers of the oil drilling filtering screen can be customized.

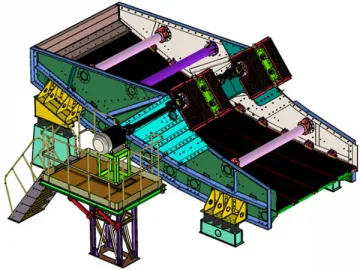

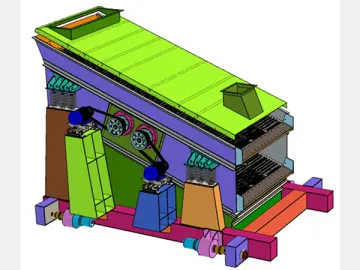

StructuralDiagram

Specifications

| Motion track | Elliptical /Linear |

| Screen type | Wave type hook edge screen |

| Mesh range | 80-200 |

| Vibrating amplitude | ≥5.5mm |

| Screen box tilt angle | -1°~ 5 ° |

| Protection grade | IP55 |

| Screen area (㎡) | 1050*2100 |

| Drilling liquid handling capacity (m3/h) | >200 |

| Solid particle diameter (μm) | ≥75 |

Links:https://www.globefindpro.com/products/64456.html