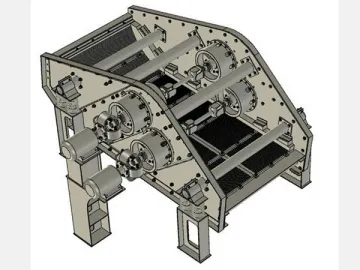

High Frequency Slime Recovery Screen

HighFrequency Slime Recovery Screen

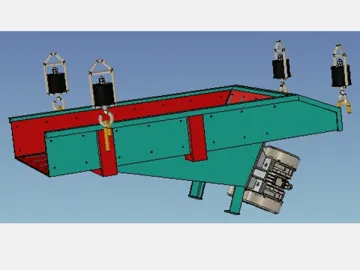

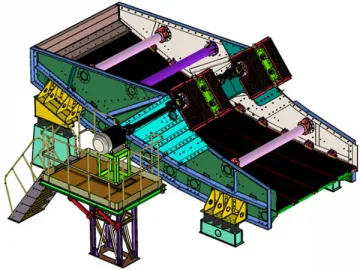

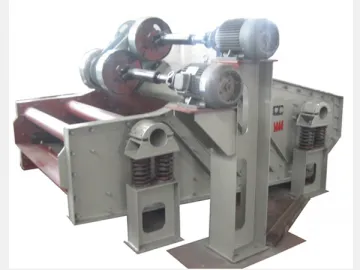

The high frequency slime recovery screen is used for recoveringcoarse slime in coal industry and gangue dehydration in mining industry.In operation, the flange vibration exciter, driven by two motors, rotates in aself-synchronous and reverse way. Thus, the screen body can move forth and back straightly toclassify and dehydrate the feedstock. The screen is characterized by highstrength vibration, high processing capacity and efficiency, low noise and longlifespan.

Specifications

| No. | Item | Unit | WGS-12*31 | WGS-14*31 | WGS-18*37 | WGS-24*48 |

| |

| 1 | Material concentration | % | ≥45 | ≥45 | ≥45 | ≥45 |

| |

| 2 | Production capacity | t/h | 15-19 | 15-19 | 28-33 | 60-120 |

| |

| 3 | Screen size | mm | 1200*3100 | 1400*3100 | 1800*3700 | 2400*4800 |

| |

| 4 | Screen mesh size | mm | 0.3,0.35 | 0.3,0.35 | 0.3,0.35 | 0.3,0.35 |

| |

| 5 | Double amplitude | mm | 3-5 | 3-5 | 3-5 | 3-5 |

| |

| 6 | Frequency | Hz | 25 | 25 | 25 | 25 |

| |

| 7 | 488 | 328 | 27 | 370 | 265 | 315 |

| |

|

8 | Motor | Model | kW | Y122M-4 | Y132S-4 | Y132M-4 | Y180M-4 |

|

| Power |

| |||||||

| Voltage |

| |||||||

| V | 380 | 380 | 380 | 380 |

| |||

| 9 | Overall dimensions | mm | 3020*2400*2100 | 3020*2600*2100 | 3527*3060*2130 | 5025*3880*2693 |

| |

| 10 | Max. single point dynamic load | N | ±200 | ±2500 | ±3500 | ±5000 |

| |

The high frequency slime recovery screen is available in specifications from 1.2m*3.1m to 2.4m*4.8m. The grizzly screen plate is made bystainless steel or polyurethane. The parts contacting feedstock and beamundergo anti-corrosive treatment which makes them highly durable and corrosionresistant. The screen adopts universal coupling or flexible coupling connection.The side plate adopts no-weld design and is riveted by HUCK bolts.

Links:https://www.globefindpro.com/products/64458.html