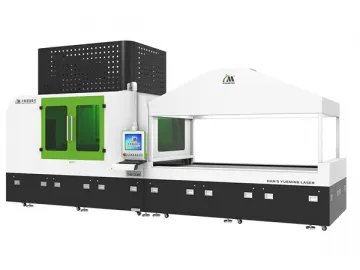

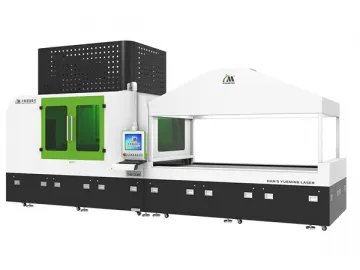

MC-DHT-A Large Surface Leather Marking Machine

Features

Fully enclosed design is safe and provides environmental protection. Humanized operating platform is simple to operate.

The entire machine body frame is welded by steel profiles and processed by artificial aging treatment, featuring concise and aesthetically pleasing appearance and high stability.

The sliding table adopts the motion system composed of imported drive parts, guide rail and servo motor, which runs smoothly and greatly improves the splicing accuracy and stability;

Imported CO2 laser source has good light spot quality and stable output power; Imported core components deliver stable performance and long service life.

Intelligent and independent board copy system can distinguish the defect of irregular leather and segment the redundant graphics, greatly improving the efficiency and process effect.

The intelligent board copy system realizes the identification and control by the Internet of things and multiple marking machines can share one board copy machine, greatly reducing the purchase cost.

Modular design facilitates transportation and realizes the free combination of different functions and customization to meet client’s needs.

Technical parameter

Laser Processing Examples:

Laser Processing Examples:

Fully enclosed design is safe and provides environmental protection. Humanized operating platform is simple to operate.

The entire machine body frame is welded by steel profiles and processed by artificial aging treatment, featuring concise and aesthetically pleasing appearance and high stability.

The sliding table adopts the motion system composed of imported drive parts, guide rail and servo motor, which runs smoothly and greatly improves the splicing accuracy and stability;

Imported CO2 laser source has good light spot quality and stable output power; Imported core components deliver stable performance and long service life.

Intelligent and independent board copy system can distinguish the defect of irregular leather and segment the redundant graphics, greatly improving the efficiency and process effect.

The intelligent board copy system realizes the identification and control by the Internet of things and multiple marking machines can share one board copy machine, greatly reducing the purchase cost.

Modular design facilitates transportation and realizes the free combination of different functions and customization to meet client’s needs.

Technical parameter

| Model | MC-DHT-A |

| Laser peak power(W) | 350 × 2 /600 × 2 |

| Working efficiency | 10-15min/pcs |

| Working area (mm) | 1400 × 2700 |

| Overall dimension(mm) | 6500 ×1900 ×3500 |

| Weight (Kg) | 1500 |

| Supply voltage | 380V, 50Hz |

| Working environment | Temperature: 20~35℃, Humidity: 5~80%. No condensate water, no dust or less dust. |

| Gross power (kW) | 18/24 |

Applicable material

This marking machine is widely used for processing large surface leather.

Scan QR to Read

Links:https://www.globefindpro.com/products/6480.html

Links:https://www.globefindpro.com/products/6480.html

Recommended Products

-

Fiber Laser Tube Cutter PCM60022-A

Fiber Laser Tube Cutter PCM60022-A

-

Automatic PVC/PE Cling Film Rewinder (with Perforation)

Automatic PVC/PE Cling Film Rewinder (with Perforation)

-

Thermal Paper Flexo Printing Machine

Thermal Paper Flexo Printing Machine

-

Laser die-cut for Label Roll FC300-B-A

Laser die-cut for Label Roll FC300-B-A

-

Alcohol Pad, Alcohol Swabs, Alcohol Prep Pad

Alcohol Pad, Alcohol Swabs, Alcohol Prep Pad

-

Semi-auto Cutterbox Blade Fixing Machine

Semi-auto Cutterbox Blade Fixing Machine

-

CMO1530-R-A Sheet and Tube Fiber Laser Cutting Machine Series

CMO1530-R-A Sheet and Tube Fiber Laser Cutting Machine Series

-

Semi-automatic Cling Film Slitter Rewinder

Semi-automatic Cling Film Slitter Rewinder

-

WTR-A Manipulator Laser Welding Machine

WTR-A Manipulator Laser Welding Machine

-

Thermal Paper Slitting Machine

Thermal Paper Slitting Machine

-

Duplex Slitter Rewinder for Nonwoven Fabric

Duplex Slitter Rewinder for Nonwoven Fabric

-

N95/KN95 Mask UV Laser Marking Machine

N95/KN95 Mask UV Laser Marking Machine