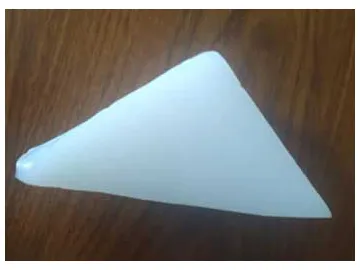

Antistatic Silicone Rubber Compound (Fumed Silica, for Molding)

Applications  Features Rapid vulcanization; Easy de-molding; EU standards compliant; Approvals

Features Rapid vulcanization; Easy de-molding; EU standards compliant; Approvals

Appearance: Translucent Processability: 160-180 Hardness (Shore A): 20 Density (g/cm3): 1.08 Tensile strength (Mpa): 5 Elongation (%): 900 Tear strength (K N/m): 12 Model: HT9930K

Appearance: Translucent Processability: 200-200 Hardness (Shore A): 30 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 900 Tear strength (K N/m): 25 Model: HT-9940K

Appearance: Translucent Processability: 220-240 Hardness (Shore A): 40 Density (g/cm3): 1.13 Tensile strength (Mpa): 7 Elongation (%): 800 Tear strength (K N/m): 35 Model: HT-9950K

Appearance: Translucent Processability: 220-240 Hardness (Shore A): 50 Density (g/cm3): 1.14 Tensile strength (Mpa): 7 Elongation (%): 650 Tear strength (K N/m): 50 Model: HT-9960K

Appearance: Translucent Processability: 230-260 Hardness (Shore A): 60 Density (g/cm3): 1.15 Tensile strength (Mpa): 7 Elongation (%): 550 Tear strength (K N/m): 50 Model: HT-9970K

Appearance: Translucent Processability: 260-280 Hardness (Shore A): 70 Density (g/cm3): 1.2 Tensile strength (Mpa): 7 Elongation (%): 450 Tear strength (K N/m): 45 Model: HT-9980K

Appearance: Translucent Processability: 250-280 Hardness (Shore A): 80 Density (g/cm3): 1.2 Tensile strength (Mpa): 7 Elongation (%): 300 Tear strength (K N/m): 20 Model: HT-9990K

Appearance: Translucent Processability: 260-290 Hardness (Shore A): 90 Density (g/cm3): 1.22 Tensile strength (Mpa): 7 Elongation (%): 200 Tear strength (K N/m): 20 Tags heat cured rubber medical grade silicone anti-static elastomers rubber molding

The antistatic silicone rubber compound is ideal for customers to produce various silicone rubber products that demand specific antistatic performance.

ROHS, REACH, FDA, FLGB, CA65, EN71-3, EN14372, PAHS, PFOA, CPSIA, siloxane testing, etc.

Test50% DBPMH (2,5-Dimethyl-2,5-di-(tert-butylperoxy) hexane), addition 1%, 175℃×5min×15Mpa

Technical Data Model: HT-9920KAppearance: Translucent Processability: 160-180 Hardness (Shore A): 20 Density (g/cm3): 1.08 Tensile strength (Mpa): 5 Elongation (%): 900 Tear strength (K N/m): 12 Model: HT9930K

Appearance: Translucent Processability: 200-200 Hardness (Shore A): 30 Density (g/cm3): 1.12 Tensile strength (Mpa): 7 Elongation (%): 900 Tear strength (K N/m): 25 Model: HT-9940K

Appearance: Translucent Processability: 220-240 Hardness (Shore A): 40 Density (g/cm3): 1.13 Tensile strength (Mpa): 7 Elongation (%): 800 Tear strength (K N/m): 35 Model: HT-9950K

Appearance: Translucent Processability: 220-240 Hardness (Shore A): 50 Density (g/cm3): 1.14 Tensile strength (Mpa): 7 Elongation (%): 650 Tear strength (K N/m): 50 Model: HT-9960K

Appearance: Translucent Processability: 230-260 Hardness (Shore A): 60 Density (g/cm3): 1.15 Tensile strength (Mpa): 7 Elongation (%): 550 Tear strength (K N/m): 50 Model: HT-9970K

Appearance: Translucent Processability: 260-280 Hardness (Shore A): 70 Density (g/cm3): 1.2 Tensile strength (Mpa): 7 Elongation (%): 450 Tear strength (K N/m): 45 Model: HT-9980K

Appearance: Translucent Processability: 250-280 Hardness (Shore A): 80 Density (g/cm3): 1.2 Tensile strength (Mpa): 7 Elongation (%): 300 Tear strength (K N/m): 20 Model: HT-9990K

Appearance: Translucent Processability: 260-290 Hardness (Shore A): 90 Density (g/cm3): 1.22 Tensile strength (Mpa): 7 Elongation (%): 200 Tear strength (K N/m): 20 Tags heat cured rubber medical grade silicone anti-static elastomers rubber molding

Scan QR to Read

Links:https://www.globefindpro.com/products/6960.html

Links:https://www.globefindpro.com/products/6960.html

Recommended Products

-

Non-Post Cure Silicone Rubber (Fumed Silica)

Non-Post Cure Silicone Rubber (Fumed Silica)

-

High Tensile & Transparent Silicone Rubber for Molding (Fumed)

High Tensile & Transparent Silicone Rubber for Molding (Fumed)

-

High Temperature HTV Silicone Rubber for Molding (Fumed Silica)

High Temperature HTV Silicone Rubber for Molding (Fumed Silica)

-

Antistatic Solid Silicone Rubber

Antistatic Solid Silicone Rubber

-

High Temperature Solid Silicone Rubber for Molding (Fumed Silica, Beige Color)

High Temperature Solid Silicone Rubber for Molding (Fumed Silica, Beige Color)

-

General Transparent Molding Silicone Rubber (Fumed)

General Transparent Molding Silicone Rubber (Fumed)

-

High Temperature Resistant Silicone Rubber for Extrusion (Red)

High Temperature Resistant Silicone Rubber for Extrusion (Red)

-

High Temperature Solid Silicone Rubber for Molding (Fumed Silica, Red Color)

High Temperature Solid Silicone Rubber for Molding (Fumed Silica, Red Color)

-

High Temperature Solid Silicone Rubber for Extrusion (with Fumed Silica, Beige Color)

High Temperature Solid Silicone Rubber for Extrusion (with Fumed Silica, Beige Color)

-

Solid Silicone Rubber with Highly Transparent (Fumed Silica, for Molding)

Solid Silicone Rubber with Highly Transparent (Fumed Silica, for Molding)

-

High Transparent Silicone Rubber for Extrusion (Fumed)

High Transparent Silicone Rubber for Extrusion (Fumed)

-

Flame Retardant Silicone Rubber

Flame Retardant Silicone Rubber

Hot Products