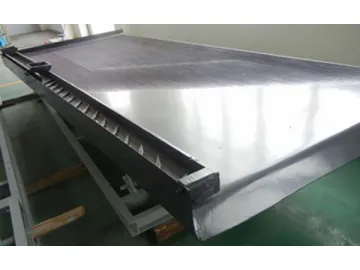

Shaking Table

Shaking tables are one of the most common mineral processing machines. The vibrating table uses gravity separation to filter out fine particles down to 0.037mm. The vibrating bed is easy to operate and can achieve high concentrates and tailings. The shaking table is suitable for the separation of tungsten, tin, tantalum, gold and other rare metals. It is also used to separate iron ore, manganese ore and coal.

Advantages

1. High enrichment rate and efficiency

2. Wear resistant vibratory bed

3. Chemical resistant

4. Water and dust proof structure

Technical Parameters

| Name | Coarse sand table surface | Fine sand table surface | Slurry table surface | |

| Bed surface dimension | Length(mm) | 4450 | 4450 | 4450 |

| Transmission side width (mm) | 1855 | 1855 | 1855 | |

| Concentrate side width (mm) | 1546 | 1546 | 1546 | |

| Feed Size (mm) | 0.5-2 | 0.074-0.5 | 0-0.074 | |

| Capacity (t/h) | 1-2.5 | 0.5-1.5 | 0.3-0.8 | |

| Feed Thickness (%) | 20-30 | 18-25 | 15-20 | |

| Water consumption(t/h) | 1-1.8 | 0.7-1 | 0.4-0.7 | |

| Stroke (mm) | 16-22 | 11-16 | 8-16 | |

| Frequency (min-1) | 240-360 | 240-360 | 240-360 | |

| Ore dressing area (m2) | 7.6 | 7.6 | 7.6 | |

| Table surface shape | Rectangle | Saw-tooth | Triangle | |

| Power (kW) | 1.1 | 1.1 | 1.1 | |

Note: No further notice if the technical parameters change.

Scan QR to Read

Links:https://www.globefindpro.com/products/69661.html

Links:https://www.globefindpro.com/products/69661.html

Recommended Products