Coarse Powder Mill

Dingbo coarse powder mill is the latest grinding equipment with multiple independent patents. It is driven by bevel gear, and very suitable for processing all kinds of ores which compressive strength is less than 320MPa, such as limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, etc. This grinding machine is mainly used in metallurgy, mining, cement, chemical, refractories, ceramics and other industries, and also applied to the highway construction, water conservancy projects, construction debris, sand processing and other fields.

Mechanical Structure and Working Principal

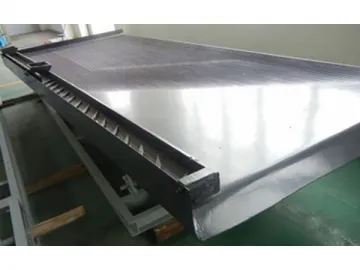

The coarse powder hammer mill is installed on an array of spindles which form to together at the rotor and axis. The crushing rotor is powered by a motor driven v-belt and is fitted with hammers that crush materials at high speeds as they are fed into the crushing chamber. Crushed stones that become small enough, pass through the grates while larger pieces are ground again until they can pass.

Feature

1. High crushing capacity is 40% higher than ball mills

2. Lower consumption (up to 50% less energy consumption than ball mills)

3. Longer lasting parts

4. Hydraulic adjustment system that is easy to use and maintain

5. Allows Moisture in raw material less than 15%;

6. Unique tent protected design

| Model | PC4008-75 | PC4012-90 | PC4015-132 |

| Rotor diameter/mm | 750 | 900 | 1150 |

| Rotor length/mm | 800 | 1200 | 1500 |

| Rotor speed r/min | 800-1000 | 800-1000 | 550-800 |

| Inlet Size /mm | 320×930 | 400×1200 | 500×1500 |

| Max feed size /mm | <30 | <40 | <50 |

| The particle size /mm | 0-3 | 0-3 | 0-8 |

| Capacity t/h | 15~30 | 30-60 | 60-100 |

| Motor Power /Kw | 75 | 90 | 132 |

| Hammerhead Quantity/a | 18 | 32 | 32 |

| Dimension L*W*H/mm | 2310×1665×1610 | 2840×2100×2020 | 3720×2650×2540 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.

Links:https://www.globefindpro.com/products/69662.html