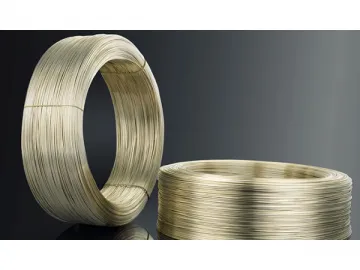

Copper-Nickel Alloy (Lead Less, Free Cutting)

Type: Bar & Wire Product-Green Alloy

Name: Lead less free cutting copper nickel alloy

Number: PW300712, PW300715, PW300718

Features

No lead, Eco-friendly(≤ 100PPM);

Easy to cut, improving processing efficiency;

Easy to weld, the lead free alloy features excellent thermal forming performance and high softening resistance in welding;

Excellent corrosion resistance; it is resistant to discoloration in sea water and air for extended periods;

Specifications of the Copper-Nickel Alloy

| Item | Size | |||

| ASTM | DIN | JIS | GB | |

| PW300712 | 1.0-15mm | |||

| PW300715 | ||||

| PW300718 | ||||

Characteristics

1. This free cutting alloy comes with excellent machinability that is much higher than that of ordinary copper-nickel-zinc alloys and can reach more than 80% of lead and zinc cupronickel alloys.

2. Lead content in this copper nickel alloy is in conformity with EU and United States' standards.

Applications

Our lead less free cutting copper nickel alloy is widely used for making pen points, glass accessories, instruments, watches, etc.

| Articles | Composition (wt% ) | Total impurity | ||||||

| Cu | Ni | Zn | Si | P | Ce | Pb | (wt% ) | |

| PW300712 | 47-49 | 11.5-12.5 | REM | 0.5-1.2 | 0.01-0.3 | 0.01-0.05 | ≤0.01 | ≤0.3 |

| PW300715 | 49-51 | 13.8-15 | REM | 0.1-1.2 | 0.01-0.3 | 0.01-0.05 | ≤0.01 | ≤0.3 |

| PW300718 | 55-57 | 16.8-18 | REM | 0.1-1.2 | 0.01-0.3 | 0.01-0.05 | ≤0.01 | ≤0.3 |

| Articles | Wire rod processing | |||||||

| Temper | Size (mm) | Tensile Strength (Mpa) | Elongation (%) | Yield Strength (Mpa) | Hardness (HV) | Density (kg/dm3) | Lead (ppm) | |

| PW300712 | M | 1.0 -15mm | 520 -600 | ≥28 | 430 -500 | 170 -190 | 8.17 | ≤100 |

| PW300715 | ||||||||

| PW300718 | Y | 740-800 | ≥4 | 630-680 | 215-225 | 8.17 | ≤100 | |

Links:https://www.globefindpro.com/products/69669.html

-

Nickel Silver Wire (for Spectacle Frame)

Nickel Silver Wire (for Spectacle Frame)

-

Vertical Shaft Impact Crusher

Vertical Shaft Impact Crusher

-

Copper-Nickel Alloy (Low-Nickel)

Copper-Nickel Alloy (Low-Nickel)

-

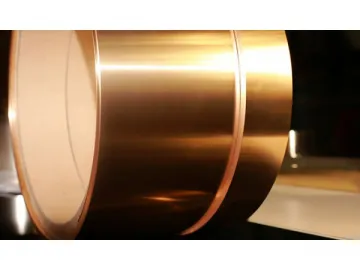

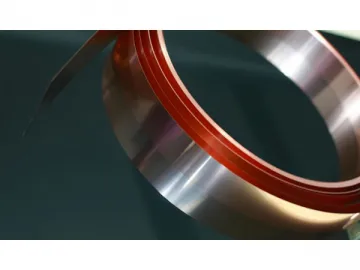

Copper Titanium Alloy Strip

Copper Titanium Alloy Strip

-

Phosphor Bronze

Phosphor Bronze

-

Copper Alloy for Precision Moulds

Copper Alloy for Precision Moulds

-

Spiral Classifier

Spiral Classifier

-

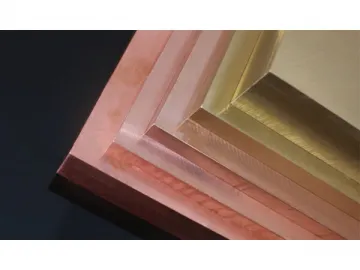

Copper Nickel Tin Alloy Strip

Copper Nickel Tin Alloy Strip

-

Copper Chromium Zirconium Alloy Strip

Copper Chromium Zirconium Alloy Strip

-

2367

2367

-

Flotation Machine

Flotation Machine

-

Coarse Powder Mill

Coarse Powder Mill