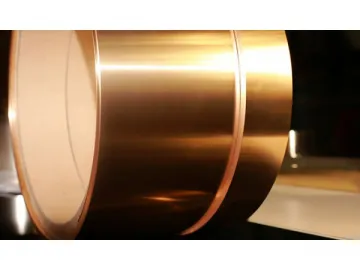

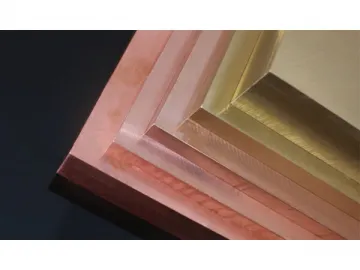

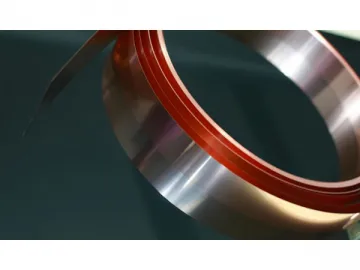

Copper-Nickel Alloy (Low-Nickel)

The copper-nickel alloy with extremely low nickel content is also called nickel free cupronickel. It comes with excellent elasticity, corrosion resistance and much lower nickel content than the international standard. The low nickel copper alloy is ideal for manufacturing glasses accessories, zippers, fasteners, decorations and other metal components. Powerway copper-nickel alloy has been listed among the new national key products and has been ranked first in the market for eight continuous years.

Low-Nickel Copper-Nickel Alloy

Chemical Compositions

Mechanical Properties

The specification and mechanical properties of PWK6907 flat wire

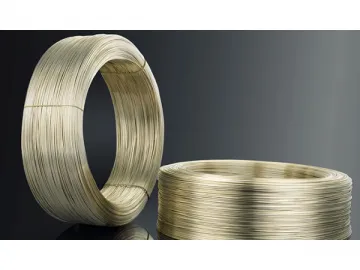

The specification and mechanical properties of PWK6907 round wire

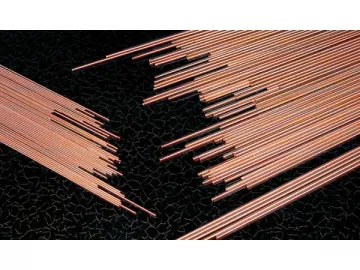

Categories: Bar & Wire Product-Green Alloy Material

Name: Copper-Nickel Alloy

Number: PWK6951, PWK6950, PWK6907

Features

0.1μg/week nickel release that is far below the requirement for less than 0.2μg/week in EN181 and EN12472 standard;

Great elasticity, modulus of elasticity> 120Gpa, higher than that of similar products in the market;

Excellent corrosion resistance;

Outstanding performance in high-temperature welding;

Slivery surface is light and eye catching ;

Low-Nickel Copper-Nickel Alloy

| Articles | Spec. | Characteristics | Applications |

| PWK6951 | 1.0-12.0mm | Excellent elasticity, corrosion-resistance, and high temperature welding performance | Glasses accessories, zippers, buttons, clothing decorations, ornaments, metal components, etc. |

| PWK6950 | 1.0-12.0mm | ||

| PWK6907 | 1.0-12.0mm |

| Articles | Chemical Compositions | Total Impurity | |||||||

| GB/QB | DIN /ASTM /JIS | Cu | Mn | Zn | Me | Ni | Si | Pb | |

| K6951 | 68-75 | 11.0-15 | REM | ≤1.5 | ≤0.5 | ≤0.1 | ≤0.1 | ≤0.2 | |

| Articles | Specification (mm) | Temper | Tensile strength (Mpa ) | Elongation (%) |

| PWK6951 PWK6950 | >3.0-10 | M | 430-500 | ≥25 |

| > 2.0-4.0 | Y8 | 490 | 23 | |

| Y4 | 520 | 17 | ||

| Y2 | 590 | 4 | ||

| Y | 690-720 | 2 | ||

| TY | ≥750 | 2 | ||

| > 1.0-2.0 | Y8 | 480 | 23 | |

| Y4 | 510 | 15 | ||

| Y2 | 590 | 12 | ||

| Y | 710-780 | 2 | ||

| TY | 750-800 | 1 |

| Specification | Temper | Tensile strength (Mpa ) | Elongation (%) |

| 0.77×3.0 | roll | 595 | 7 |

| 0.9-1.0×3.9-4.0 | roll | 560-615 | 6-9 |

| 1.05-1.25×3.3-4.8 | roll | 580-630 | 5-13 |

| Specification | Temper | Tensile strength (Mpa ) | Elongation (%) |

| dia2.0 - 3.0 | Y8 | 500-530 | 22-28 |

| dia2.2-4.2 | M | 470-510 | 31-37 |

Scan QR to Read

Links:https://www.globefindpro.com/products/69672.html

Links:https://www.globefindpro.com/products/69672.html

Recommended Products

-

Copper Titanium Alloy Strip

Copper Titanium Alloy Strip

-

Phosphor Bronze

Phosphor Bronze

-

Copper Alloy for Precision Moulds

Copper Alloy for Precision Moulds

-

Free Cutting Bronze

Free Cutting Bronze

-

Brass Alloy (Energy-Efficient)

Brass Alloy (Energy-Efficient)

-

Brazing Alloy / Filler Metal

Brazing Alloy / Filler Metal

-

Vertical Shaft Impact Crusher

Vertical Shaft Impact Crusher

-

Nickel Silver Wire (for Spectacle Frame)

Nickel Silver Wire (for Spectacle Frame)

-

Copper-Nickel Alloy (Lead Less, Free Cutting)

Copper-Nickel Alloy (Lead Less, Free Cutting)

-

Spiral Classifier

Spiral Classifier

-

Copper Nickel Tin Alloy Strip

Copper Nickel Tin Alloy Strip

-

Copper Chromium Zirconium Alloy Strip

Copper Chromium Zirconium Alloy Strip

Hot Products