High Conductivity Copper Alloy

Here at Powerway Alloy, as one of the major developers and producers of high performance copper alloy products in China, we carry a wide range of copper chrome zirconium materials. The chromium zirconium copper delivers a combination of high strength and high conductivity. It has brought dramatic benefits to various sectors, including automobile, aerospace and metallurgy industries.

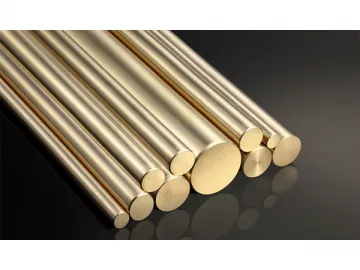

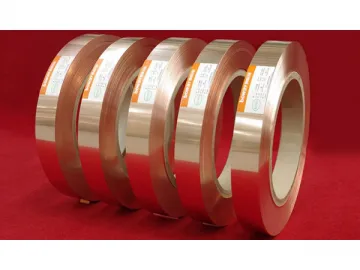

Categories: Bar & Wire Product- High Conductivity Copper Alloy

Name: Copper Chrome Zirconium

Number: C18150, C18200, C15000

Features

High strength: Tensile strength> 450Mpa;

High hardness: HRB70-86, HB120-165;

High conductivity: Conductivity>75% (IACS);

High softening point: 475-600℃;

High wear and heat resistance;

High resistance to deformation;

Long service life;

Details of the Copper Chrome Zirconium

| Items | Specifications | Characteristics | |||

| ASTM | DIN | JIS | GB | ||

| C18150 | CuCr1Zr | - | - | φ6-φ120mm 10 S6-S65mm | 1. High strength (Rm:≥450Mpa, HRB:70-86) 2. High conductivity (75-83% conductivity in IACS) 3. Excellent resistance to high temperature, abrasion, and deformation. |

| C15000 | CuZr | - | QZr0.2 | φ6-φ120mm 10 S6-S65mm | |

| C18200 | CuCr1 | - | - | φ6-φ120mm 10 S6-S65mm | |

Applications

Copper chrome zirconium is ideally suited for the resistance welding of steel plates and stainless steel plates for the automobile and aerospace industry. It is also an ideal material for spot welding and circuit breakers in high voltage switches. Additionally, this high strength and high conductivity material is perfect for continuous crystallizers in the metallurgical industry and widely used as lead alternatives for IC frames.

Chemical Compositions

| Articles | Composition | ||||

| GB/QB | DIN/ASTM/JIS | Cr | Zr | Total impurity | Cu |

| QCr0.5Zr0.15 | C18150 | 0.5-1.5 | 0.05-0.25 | REM | |

| QCr0.5 | C18200 | 0.6-1.2 | - | REM | |

| QZr0.2 | C15000/C15100 | - | 0.1-0.2 | REM | |

| QZr0.4 | - | - | 0.3-0.5 | REM | |

| Description | Articles | Temper | Specification (mm) | Tensile Strength (Mpa ) | Elongation ( % ) | Hardness |

| Chromium Bronze | C18200 | TH04 | 4-20 | >380 | >10 | 75-80 |

| 20-40 | >475 | >10 | 72-80 | |||

| 40-60 | >450 | >8 | 65-75 | |||

| Chromium -zirconium copper | C18150 | TH04 | 4-20 | >450 | >10 | 75-85 |

| 20-40 | >400 | >10 | 73-85 | |||

| 40-60 | >380 | >12 | 65-83 | |||

| Zirconium copper | C15000/C15100 | TH04 | 4-20 | >450 | >10 | 75-85 |

| 20-40 | >400 | >10 | 73-85 | |||

| 40-60 | >380 | >8 | 68-83 |

Links:https://www.globefindpro.com/products/69687.html