Ball Mill

Ball mill is used for grinding materials which have been crushed, it is suitable for cement, silicate products, new building materials, refractory materials, chemical fertilizer, ferrous and non-ferrous metals, glass ceramics and other industries. All kinds of ores can be dry or wet grinding by this mill. Our milling machine can be used for processing barite, calcite, limestone, dolomite, marble, bentonite, talc, mica, graphite, phosphate rock, potash, pumice, and so on. This grinding machine can be divided into grid type and overflow type according to the discharging way of ores.

Working Principle

The centrifugal force generated by the rotation of the roller which can drive the steel ball moving, and impact the materials repeatedly. The following is a detailed process of ball mill: Materials enter the first bin of the mill through feeding device, where is equipped with stepped liner board or corrugated liner board, and steel balls with various of sizes. This bin is used for coarse grinding of the materials. After that the materials enter the second bin of the mill, where is equipped with flat liner board and steel balls, and this bin is used for fine grinding of the materials. The finished powder is discharged by discharge grate.

Advantages

1. When the diameter of the rod mill is less than 3200mm compared to its conventional configuration, is using a rolling bearing instead of a sliding bush bearing which has energy savings of 20-30%

2. When the diameter of the grinding mill is more than 2700mm of its normal configuration, it is in slow operation for maintenance purposes.

3. Drum feeder, spiral feeder and joint feeder options.

4. The lubrication system uses a thin oil lubricant that is easily applied to the machine.

5. Bearings are lubricated by an automatic grease pump.

6. A series and B series liner plate options. B series plates can save up to 10-20% energy.

Technical Specification

| Model | rotary speed (r/min) | Loading ball weight(t) | Input size(mm) | Discharge size(mm) | Capacity(t/h) | Motor power(kw) | Weight(t) |

| Ф900×1800 | 37 | 1.9 | ≤15 | 0.075-0.89 | 0.5-2 | 15 | 3.4 |

| Ф900×2100 | 37 | 2.3 | ≤15 | 0.075-0.4 | 0.4-2 | 18.5 | 3.9 |

| Ф1200×2000 | 35 | 3.85 | ≤25 | 0.074-0.4 | 1.1-2.5 | 30 | 7.78 |

| Ф1200×2400 | 335 | 4.6 | ≤25 | 0.074-0.4 | 1.3-3.2 | 37 | 10.02 |

| Ф1500×3000 | 29 | 9 | ≤25 | 0.074-0.4 | 3.3-8.2 | 75 | 14.122 |

| Ф1500×5700 | 29 | 17 | ≤25 | 0.074-0.4 | 2.6-14 | 110 | 25 |

| Ф1830×3000 | 24 | 13.5 | ≤25 | 0.074-0.4 | 4~15 | 135 | 28 |

| Ф1830×4500 | 24 | 20 | ≤25 | 0.074-0.4 | 4-19 | 155 | 32 |

| Ф1830×7000 | 24 | 31.5 | ≤25 | 0.074-0.4 | 6.22 | 210 | 37.5 |

| Ф2100×3600 | 22 | 21.5 | ≤25 | 0.074-0.4 | 7.6-28 | 210 | 43.454 |

Other Pictures

Links:https://www.globefindpro.com/products/69694.html

-

Environmentally Friendly Brass (for Bathroom)

Environmentally Friendly Brass (for Bathroom)

-

Aluminum Bronze

Aluminum Bronze

-

Flotation Cell

Flotation Cell

-

Deformed Copper-Nickel Alloys (Low-Nickel)

Deformed Copper-Nickel Alloys (Low-Nickel)

-

Impact Fine Crusher

Impact Fine Crusher

-

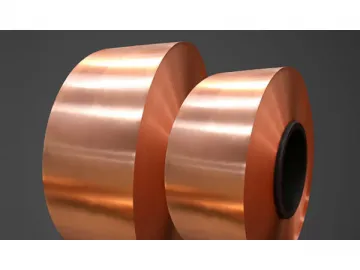

Phosphor Bronze Strip

Phosphor Bronze Strip

-

Belt Conveyor

Belt Conveyor

-

High Pressure Suspension Mill

High Pressure Suspension Mill

-

Superelastic Alloys

Superelastic Alloys

-

Dewatering Screen

Dewatering Screen

-

High Conductivity Copper Alloy

High Conductivity Copper Alloy

-

Ultrafine Mill (Three Rings)

Ultrafine Mill (Three Rings)