Flotation Cell

Description

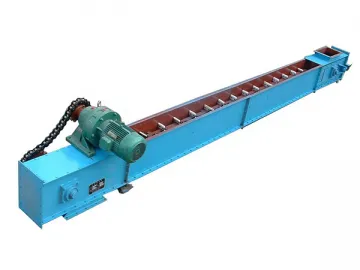

Our flotation cell separates nonferrous metal, ferrous metal, nonmetallic and chemical materials and recycled minerals. Though no auxiliary equipment is needed, the coal equipment must be installed on level ground. Easy to adjust or change the flow of the machine, this flotation cell greatly reduces the impurities in the materials by automatically cycling the slurry through its chutes several times. With an upper and lower retroversion blade, the impeller can move the slurry up or down as needed.

Other Images

Other Images

Specifications of Flotation Cell

Our flotation cell separates nonferrous metal, ferrous metal, nonmetallic and chemical materials and recycled minerals. Though no auxiliary equipment is needed, the coal equipment must be installed on level ground. Easy to adjust or change the flow of the machine, this flotation cell greatly reduces the impurities in the materials by automatically cycling the slurry through its chutes several times. With an upper and lower retroversion blade, the impeller can move the slurry up or down as needed.

Features

Efficient

Low energy consumption

Easy to maintain and operate

Working Principle

During operation, the mineral processing plant suctions in slurry from the bottom of the trough to in between impellers. Low-pressure air is fanned in through a hollow shaft, which mixes the slurry evenly and returns it to the trough. The froth from the mixing overflows into another trough where the ore sinks to the bottom where it will be remixed with the air while the remaining liquid flows unimpeded into the next trough, leaving the ore residue behind.

Specifications of Flotation Cell

| Type | SF0.37 | SF0.7 | SF1.2 | SF2.8 | SF4 | |

| Volume (m3) | 0.37 | 0.7 | 1.2 | 2.8 | 4 | |

| Diameter of impeller (mm) | 300 | 350 | 450 | 550 | 650 | |

| Capacity (m3/min) | 0.2-0.4 | 0.3-0.9 | 0.6-1.2 | 1.5-3.5 | 0.5-4 | |

| Speed of impeller (m3/min) | 352 | 400 | 312 | 268 | 238 | |

| Motor | Type | Y90L-4 | Y100L2-4 | Y132M2-6 | Y160L-6 | Y180L-6 |

| Y90S-4 | Y90S-4 | Y90S-4 | Y90S-4 | Y90L-4 | ||

| Power ( kw ) | 1.5 | 3 | 5.5 | 11 | 15 | |

| 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | ||

| Overall dimensions (mm) | 700× 700× 750 | 900× 820× 950 | 1100× 1100× 1100 | 1700× 1600× 1150 | 1850× 2050× 1200 | |

| Weight (kg) | 468 | 600 | 1373 | 2338 | 2660 | |

Scan QR to Read

Links:https://www.globefindpro.com/products/69697.html

Links:https://www.globefindpro.com/products/69697.html

Recommended Products

Hot Products