Magnetic Separator

The magnetic separator is designed to separate raw materials with different magnetic rigidities, recovering ferromagnetic materials. At the core of each separator is a unique, efficient magnetic system. The metal separators are available in several designs and sizes for different applications. The magnetic separators are available in cyclic design with process vessel diameters from 220mm to 3,050mm.

The magnetic separator has a short magnetic circuit, little magnetic flux leakage, high magnetic intensity, and low energy consumption. With its simple structure and easy maintenance, they are used in more than 20 mineral processing plants in China.

Features

1. Can be used in with low grade ore

2. Tailing reclaim

3. Purifies dry powdered sulfuric-acid residue

4. Removes iron from non-ferromagnetic material

5. Purifies concentrated powder

Working Principle

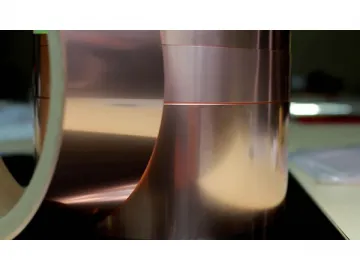

Our mineral processing plant efficiently separates magnetic minerals, such as hematite, limonite, wolfram, ilmenite, and tantalum-niobium. In recent years, it has also been applied to purifying quartz, feldspar and nephline. Its magnetic system features a ring-shaped, closed magnetic circuit with energizing coils made of copper tubes that are cooled internally by water. Grooved plates made of magnetic conductive stainless steel are used as a magnetic matrix.

| Model | Dimension of Cylinder | Capacity (m3) | Power (KW) | Rotating Speed (r/min) |

| CTB44 | 400x600 | 3 | 1.1 | 45 |

| CTB46 | 400x600 | 5 | 1.1 | 45 |

| CTB66 | 600x600 | 16 | 1.1 | 40 |

| CTB69 | 600x900 | 24 | 1.1 | 40 |

| CTB612 | 600x1200 | 32 | 2.2 | 40 |

| CTB618 | 600x1800 | 48 | 2.3 | 40 |

| CTB712 | 750x1200 | 48 | 3 | 35 |

| CTB718 | 750x1800 | 72 | 3 | 35 |

| CTB1050 | 1050x1800 | 95 | 4 | 30 |

| Model | Drum Dimension (D×L)(mm) | Belt Width (mm) | Magnetic Intensity | Feeding Size (mm) | Capacity (t/h) |

| XCT465 | 400×650 | 500 | 1600-4500 gauss | <70 | 5 |

| XCT565 | 500×650 | 500 | <70 | 10 | |

| XCT665 | 600×650 | 500 | <70 | 15 | |

| XCT68 | 600×800 | 650 | <80 | 20 | |

| XCT758 | 750×800 | 650 | 1600-5500 gauss | <80 | 25 |

| XCT7595 | 750×950 | 800 | <80 | 30 | |

| XCT995 | 900×950 | 800 | <80 | 150-210 | |

| XCT10115 | 1000×1150 | 1000 | <80 | 350-430 |

Links:https://www.globefindpro.com/products/69715.html